In the world of fluid dynamics and mechanical engineering, the efficiency and reliability of pumps play a crucial role in various industries, from automotive to marine applications. Among the key components of a pump, the impeller stands out as a vital element that dictates its performance. In this article, we delve into the significance of cast iron impellers in pump systems, exploring their manufacturing process, benefits, and applications.

Understanding Impeller Dynamics

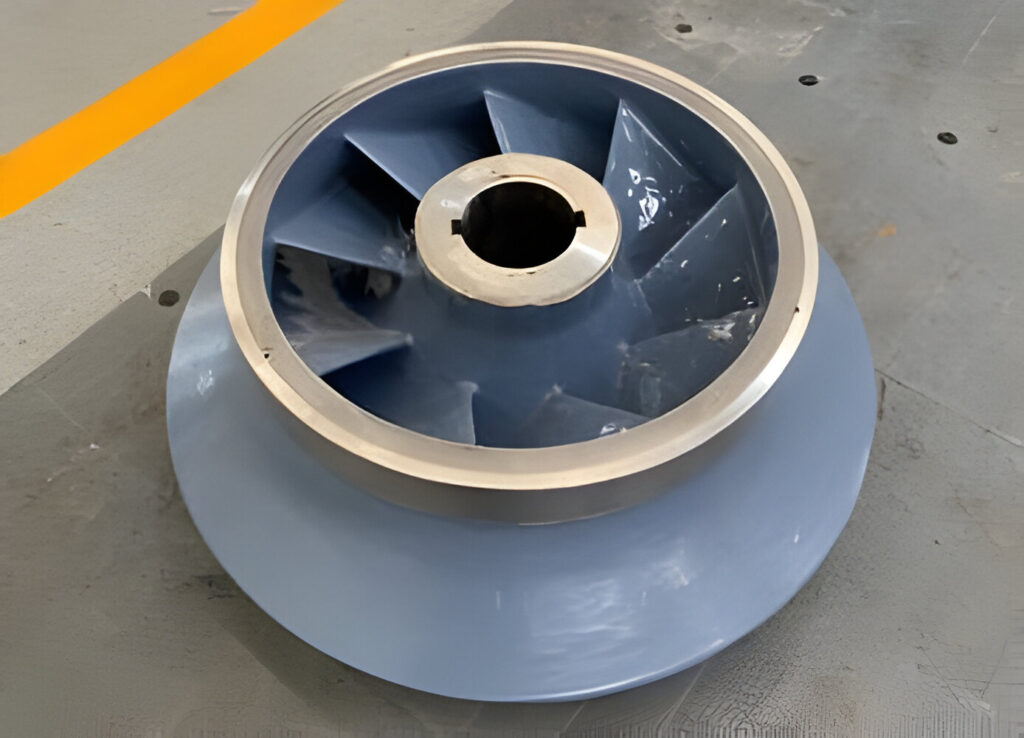

Impellers are dynamic components within pumps responsible for imparting kinetic energy to the fluid being pumped. By rotating at high speeds, impellers generate centrifugal force, pushing the fluid outward and increasing its velocity. This kinetic energy is then converted into pressure energy as the fluid passes through the pump's diffuser or volute casing.

There are various types of impellers, including closed, open, semi-open, and vortex. Each type is designed to cater to specific flow rate and head requirements, making impeller selection a critical aspect of pump design and optimization.

The Significance of Cast Iron Impellers

Among the materials used for impeller construction, cast iron holds a prominent position due to its exceptional mechanical properties and cost-effectiveness. Cast iron impellers offer high strength, corrosion resistance, and excellent machinability, making them suitable for a wide range of pumping applications.

One of the key advantages of cast iron impellers is their ability to withstand abrasive and corrosive environments. In industries such as mining, wastewater treatment, and agriculture, where pumps are exposed to harsh conditions, cast iron impellers provide longevity and reliability.

Moreover, cast iron impellers can be manufactured using various casting processes, including sand casting and investment casting. These processes allow for intricate designs and precise dimensions, ensuring optimal pump performance.

Manufacturing Process of Cast Iron Impellers

The manufacturing process of cast iron impellers typically involves the following steps:

- Pattern Making: A pattern, representing the final shape of the impeller, is created using wood, metal, or plastic.

- Molding: The pattern is used to create molds, either made of sand or investment material, depending on the casting process employed.

- Casting: Molten cast iron is poured into the mold cavity, where it solidifies to form the impeller shape.

- Finishing: Once the casting has cooled, it undergoes various finishing processes, such as machining, grinding, and polishing, to achieve the desired surface finish and dimensional accuracy.

By leveraging advanced casting techniques and modern machining capabilities, manufacturers can produce high-quality cast iron impellers that meet stringent performance requirements.

Applications of Cast Iron Impellers

Cast iron impellers find widespread applications across numerous industries, including:

- Automotive: In automotive water pumps, cast iron impellers ensure efficient coolant circulation, preventing engine overheating.

- Marine: Boat water pump impellers utilize cast iron impellers to facilitate water intake and circulation for cooling systems.

- Industrial: Centrifugal pumps used in industrial processes rely on cast iron impellers to handle abrasive slurries and corrosive fluids effectively.

- Agricultural: Irrigation pumps equipped with cast iron impellers deliver reliable water distribution for agricultural operations.

In addition to these applications, cast iron impellers are also utilized in pool pumps, fuel pumps, and HVAC systems, demonstrating their versatility and adaptability across various sectors.

Cast iron impellers play a vital role in enhancing the performance and reliability of pump systems across diverse industries. With their exceptional mechanical properties, corrosion resistance, and cost-effectiveness, cast iron impellers continue to be the preferred choice for demanding pumping applications. By understanding the manufacturing process and applications of cast iron impellers, businesses can make informed decisions to optimize pump performance and achieve operational excellence.