In the rapidly evolving landscape of industrial manufacturing, the demand for efficient, durable, and lightweight solutions has led to significant advancements in motor housing technology. A key player in this revolution is aluminum motor housing, particularly those produced using advanced die casting techniques. As a leading aluminum housing motor supplier, KT Foundry is at the forefront of providing high-quality solutions that cater to a myriad of industrial applications.

Understanding Aluminum Motor Housings

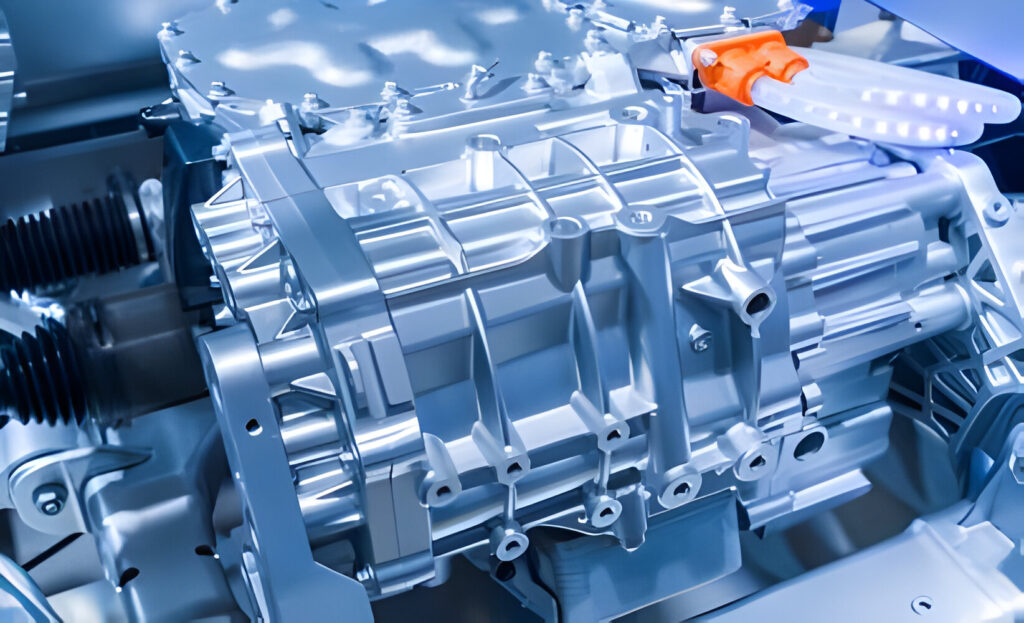

Aluminum motor housings are integral components in various types of motors, including servo motors and electric motors. These housings serve as protective shells that house the motor’s internal components, such as windings, bearings, and rotors. The primary function of these housings is to provide structural stability, protect the motor from environmental factors, and aid in heat dissipation.

The use of aluminum in motor housings is particularly advantageous due to the metal's lightweight nature, excellent thermal conductivity, and corrosion resistance. These characteristics ensure that the motors are not only lighter, which is essential for applications requiring high mobility and reduced energy consumption, but also more efficient in terms of heat management and longevity.

Manufacturing Excellence in Die Casting

KT Foundry specializes in aluminum die casting for motor housings, employing state-of-the-art technology to ensure precision and quality. Die casting is a preferred method for manufacturing motor housings because it allows for high production rates, consistent part quality, and the ability to create complex shapes and detailed features, which are often required in motor housings.

Our process involves injecting molten aluminum under high pressure into a steel mold or die. This technique is ideal for producing high volumes of uniform parts with excellent surface finish and dimensional accuracy. The result is motor housings that meet the rigorous standards required for both performance and aesthetics.

Applications and Industry Scenarios

Aluminum motor housings are ubiquitous across various sectors such as automotive, aerospace, industrial automation, and consumer electronics. In the automotive industry, for instance, aluminum motor housings are crucial for electric vehicles (EVs) and hybrid systems, where efficiency and weight reduction are paramount.

In aerospace, the reduced weight of aluminum housings contributes significantly to energy efficiency, a crucial factor in aircraft performance and operational cost reduction. Industrial automation also benefits from the durability and heat dissipation characteristics of aluminum motor housings, ensuring that machinery operates smoothly under continuous use.

FAQs and Customer Inquiries

Customers often inquire about the customization capabilities and the specific properties of aluminum motor housings. At KT Foundry, we offer customizable solutions tailored to meet unique requirements. We address common questions regarding the thermal properties, weight specifications, and the environmental resistance of our aluminum motor housings, providing detailed data to support client decisions.

Invitation to Connect

For those interested in learning more about our aluminum motor housings and other products, we invite you to visit our website at kt-foundry. Our team is eager to discuss how our solutions can meet your needs and help drive your projects forward. Contact us today to explore the possibilities that our cutting-edge aluminum die casting solutions can offer.