Aluminum experimental motor casings represent a pioneering approach to enhancing the performance and reliability of electric motors through innovative design and material selection. As industries continue to push the boundaries of technological advancement, aluminum experimental motor casings emerge as a promising solution, offering a combination of lightweight construction, durability, and versatility. In this article, we delve into the features, advantages, and potential applications of aluminum experimental motor casings, showcasing their role in driving innovation and meeting the evolving needs of modern industries.

Features of Aluminum Experimental Motor Casings

Aluminum experimental motor casings boast several key features that differentiate them from traditional motor housing solutions:

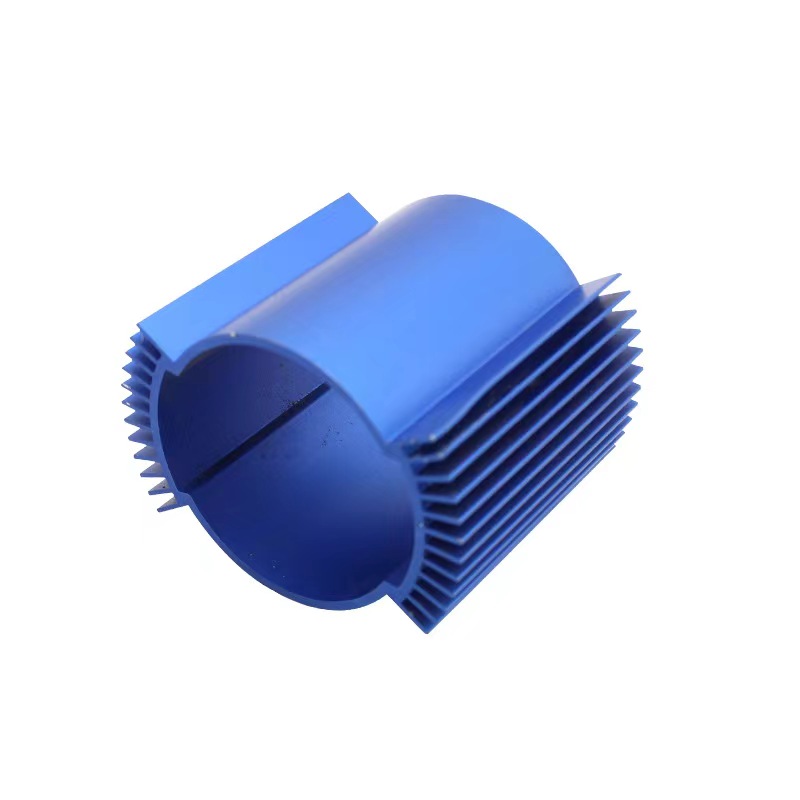

- Advanced Design: Aluminum experimental motor casings are designed with precision engineering techniques to optimize performance and functionality. From intricate internal channels for improved heat dissipation to reinforced structural elements for enhanced durability, every aspect of the design is carefully crafted to meet specific requirements.

- Lightweight Construction: Utilizing aluminum as the primary material enables the production of lightweight motor casings without compromising strength or durability. This lightweight construction contributes to overall system efficiency and reduces the weight of electric motors, making them more suitable for a wide range of applications.

- Customization Options: Aluminum experimental motor casings offer flexibility in design and customization, allowing for tailored solutions to meet the unique needs of different industries and applications. Whether it's specific dimensions, mounting configurations, or additional features, aluminum casings can be adapted to suit diverse requirements.

Advantages of Aluminum Experimental Motor Casings

The adoption of aluminum experimental motor casings offers numerous advantages for various industrial applications:

- Improved Thermal Management: Aluminum's excellent thermal conductivity enables efficient heat dissipation from the motor's internal components, ensuring optimal operating temperatures and prolonging component lifespan. Enhanced thermal management contributes to overall system reliability and performance.

- Enhanced Durability: Aluminum experimental motor casings are engineered to withstand the rigors of demanding operating conditions, including temperature fluctuations, mechanical stress, and environmental factors. Their robust construction ensures long-term durability and reliability in industrial settings.

- Potential for Performance Optimization: The lightweight nature of aluminum experimental motor casings allows for reduced inertia and improved dynamic response, leading to enhanced motor performance and efficiency. This optimization potential makes aluminum casings suitable for high-speed and precision applications.

Applications of Aluminum Experimental Motor Casings

Aluminum experimental motor casings hold promise for a wide range of industrial applications, including:

- Automotive: In the automotive industry, aluminum experimental motor casings can be utilized in electric vehicle (EV) drivetrains, hybrid powertrains, and auxiliary systems to improve efficiency, reduce weight, and enhance performance.

- Aerospace: Aluminum experimental motor casings offer lightweight, durable solutions for aerospace applications, including aircraft propulsion systems, actuation systems, and avionics.

- Renewable Energy: In the renewable energy sector, aluminum experimental motor casings can be employed in wind turbines, solar tracking systems, and hydroelectric generators to optimize performance and reliability while minimizing environmental impact.

Experience the KT Foundry Advantage

At KT Foundry, we specialize in manufacturing high-quality aluminum experimental motor casings tailored to meet the unique requirements of our clients. With state-of-the-art facilities, advanced manufacturing processes, and a team of experienced professionals, we are committed to delivering innovative solutions that exceed expectations.

Explore our website (kt-foundry) to learn more about our aluminum experimental motor casing products and how they can enhance the performance and reliability of your electric motor applications. Contact us today to discuss your specific needs and experience the KT Foundry advantage firsthand.