Aluminum die casting is a pivotal technology in modern manufacturing, especially in the automotive and electronics industries. The versatility and superior properties of aluminium make it an ideal choice for producing complex, lightweight, and robust components such as crank housings and motor enclosures. This article delves into the technology behind aluminum die cast crank housings, explores various motor housing designs, and illustrates the practical applications of these components in various industries.

Aluminum Die Cast Crank Housing: An Overview

Crank housings are critical components in engines, providing the necessary enclosure for the crankshaft and associated moving parts. Aluminium, with its excellent strength-to-weight ratio, has become the material of choice for these housings. Aluminum die casting allows for the creation of highly precise and durable crank housings that can withstand the rigors of engine operation while contributing to overall weight reduction. This not only enhances fuel efficiency but also improves the vehicle's handling characteristics.

Advancements in Motor Housing Technologies

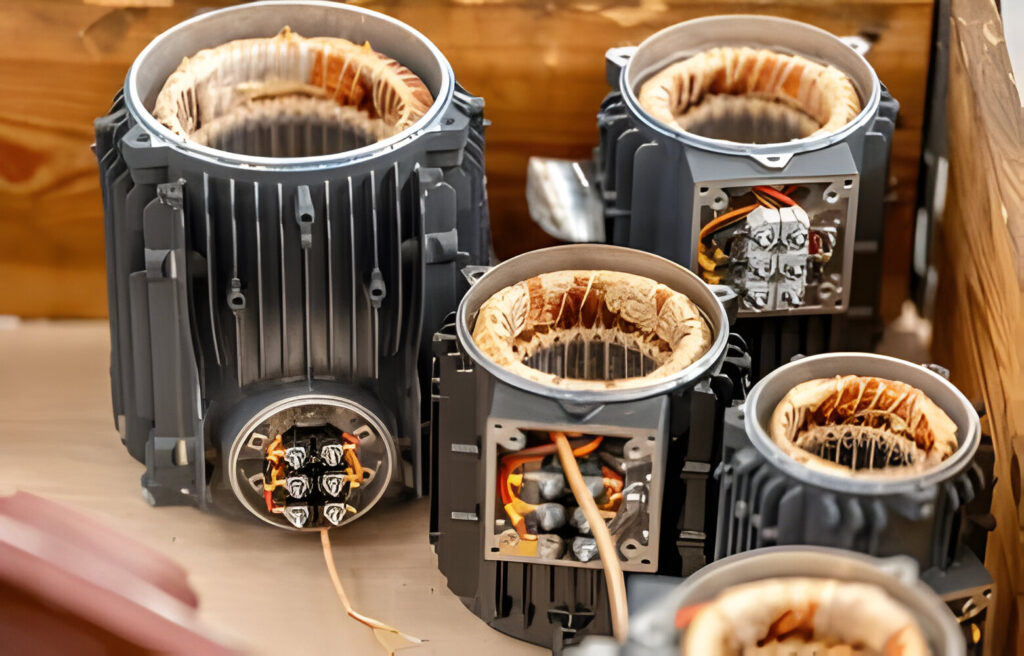

Motor housings, essential for protecting and cooling electric motors, have seen significant advancements thanks to aluminum die casting. From servo motor housing to electric motor casings, aluminum's thermal conductivity and corrosion resistance are critical. These properties ensure that the motor operates efficiently and with a prolonged service life, which is particularly crucial in high-demand applications such as industrial automation and automotive electric systems.

Product Spotlight: Aluminum Die Casting Housing Solutions

Our range of die cast aluminum housings includes options for various applications:

- Servo Motor Housing: Designed for precision and durability, our servo motor housings cater to a broad spectrum of industrial applications.

- Electric Motor Housing: Ideal for both AC and DC motors, these housings are designed to optimize heat dissipation and protect sensitive components.

- Motor Housing Parts: We offer a complete range of parts including covers and casings, all benefiting from the precision and quality of aluminum die casting.

Practical Applications

The practical applications of aluminum die cast crank housings and motor enclosures are vast. In the automotive sector, they are used not only in traditional combustion engines but also in electric vehicles to house batteries and electric motors. In robotics, servo motor housings made from aluminum protect the motor and gear assembly, ensuring that robots can operate smoothly under various conditions.

Beyond these, our products find applications in aerospace for lightweight yet sturdy components, in marine environments where corrosion resistance is paramount, and in consumer electronics where compact and efficient designs are necessary.

Engage with Us

At KT Foundry, we specialize in aluminum die casting for a variety of applications. Our expertise in crafting high-quality motor housings and crank housings ensures that you receive products that meet the highest standards of durability and performance. To learn more about how our aluminum die casting solutions can benefit your projects, visit our website at kt-foundry. Connect with us today to discuss your specific needs and how we can assist in achieving your production goals.