In today's rapidly evolving industrial landscape, the demand for durable and efficient component housings in electronics and machinery is more significant than ever. Among the plethora of materials and processes available, aluminium die casting stands out as a superior choice, particularly for LED housings and motor enclosures. This article delves into the merits of aluminium die casting, highlighting its pivotal role in producing robust LED housings and versatile motor enclosures.

Aluminium Die Casting for LED Housings

LED lighting technology has become ubiquitous due to its efficiency and longevity. However, the performance of LED lights is heavily dependent on the quality of their housings, which must offer excellent heat dissipation and protection against environmental factors. Aluminium, known for its outstanding thermal conductivity and corrosion resistance, is ideally suited for this task. Through the process of die casting, aluminium can be precisely molded into complex shapes, ensuring that LED housings meet the exact specifications for optimal performance.

The die casting process for aluminium involves injecting molten aluminium into a steel mold at high pressure. This method allows for high production rates and exceptional dimensional accuracy, making it cost-effective for manufacturing LED housings on a large scale. Additionally, the surface of die-cast aluminium can be easily finished with coatings or treatments to enhance its appearance and durability.

Expanding the Scope: Aluminium Motor Housings

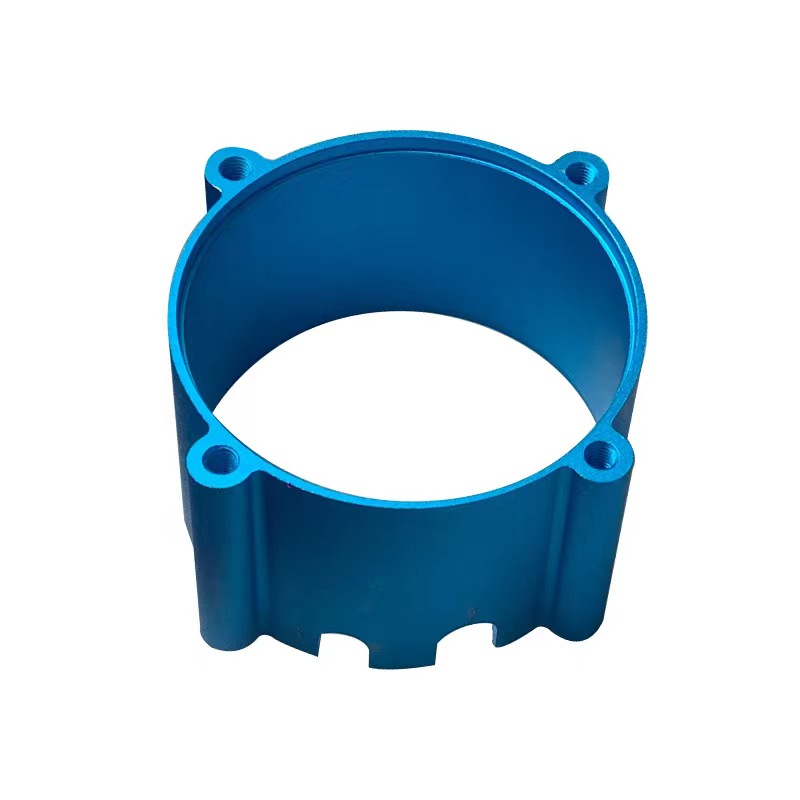

Beyond LED lighting, aluminium die casting is instrumental in fabricating motor housings for various applications, including servo motors and electric motors. Motor housings are crucial for protecting the motor's internal components from dust, moisture, and mechanical damage, while also aiding in heat dissipation.

Aluminium's lightweight yet sturdy nature makes it an excellent material for motor enclosures, particularly in applications where reducing weight is essential, such as in automotive and aerospace industries. The adaptability of die casting allows for the integration of additional features into the motor housing, such as cooling fins or mounting brackets, without compromising structural integrity.

Practical Applications and Customer Benefits

The practical applications of aluminium die-cast LED housings and motor enclosures are vast. In the automotive industry, LED lights with die-cast housings are used for headlights and interior lighting, where reliability under harsh conditions is crucial. Similarly, aluminium motor housings are extensively used in electric vehicles to encase the motors that drive the wheels, providing both protection and thermal management.

For manufacturers and suppliers, transitioning to aluminium die casting for component housings can significantly enhance product reliability and appeal. Products crafted with precision and designed for performance resonate well with technologically inclined markets and environmentally conscious consumers.

Why Choose KT Foundry for Your Die Casting Needs?

At KT Foundry, we specialize in high-quality aluminium die casting for LED housings and motor enclosures. Our state-of-the-art casting facilities are equipped to handle both high-volume production runs and custom small-batch orders, ensuring that we can meet the diverse needs of our clients. By partnering with us, you gain access to our expert design and engineering team, who are committed to developing innovative solutions that boost product performance and reduce manufacturing costs.

We invite you to explore how our aluminium die casting solutions can transform your product offerings. Visit our website at kt-foundry to learn more about our capabilities and to discuss your project requirements with our specialists.