Low Alloy Steel casting

Low Alloy Steel casting

Low alloy steel casting involves the process of pouring molten low alloy steel into a mold to create specific parts. This type of steel contains small amounts of additional elements like chromium, nickel, or molybdenum, which enhance its mechanical properties. The result is a material with improved strength, hardness, and resistance to wear and corrosion, making it suitable for demanding applications in industries such as automotive, aerospace, and construction.

Common Low Alloy Steel Grades for Casting

| C | Si | Mn | Cr | Mo | P≤ | S≤ | Ni | |

| 42CrMo | 0.38-0.45 | 0.17-0.37 | 0.50-0.80 | 0.90-1.20 | 0.15-0.25 | |||

| 35CrMo | 0.32-0.40 | 0.17-0.37 | 0.40-0.70 | 0.80-1.10 | 0.15-0.25 | |||

| 40CrNiMo | 0.37-0.44 | 0.17-0.37 | 0.50-0.80 | 0.60-0.90 | 0.15-0.25 | 1.25-1.65 | ||

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | 0.80-1.10 | 0.15-0.25 | 0.035 | 0.04 | |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-0.10 | 0.80-1.10 | 0.15-0.25 | 0.035 | 0.04 | |

| 8630 | 0.28-0.33 | 0.15-0.35 | 0.70-0.90 | 0.40-0.60 | 0.15-0.25 | 0.035 | 0.04 | 0.40-0.70 |

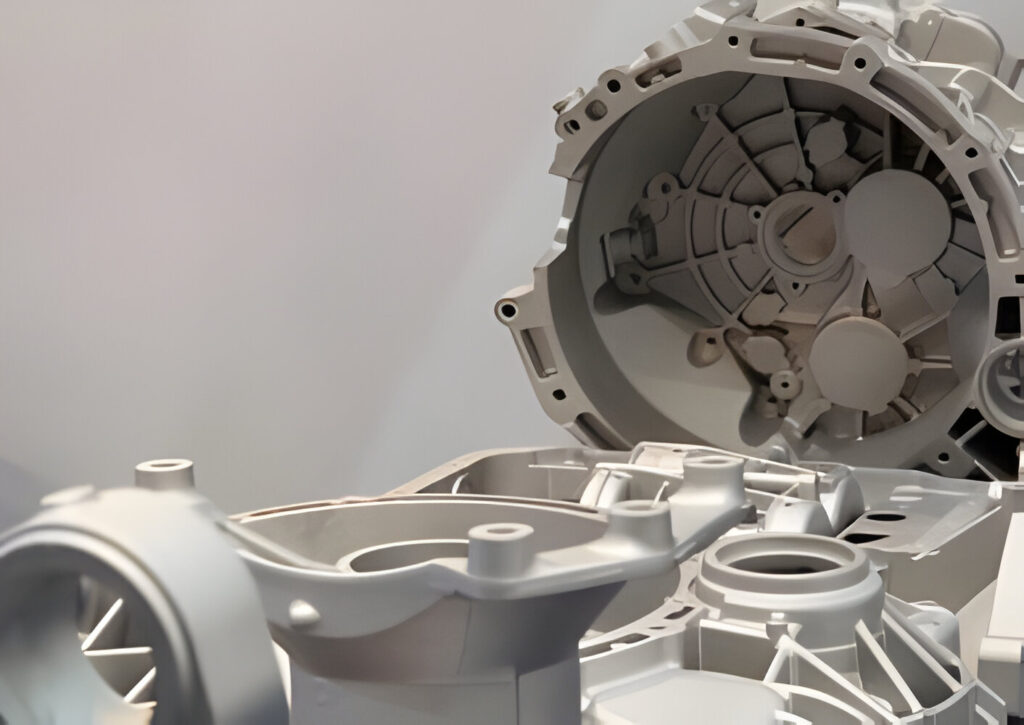

Our alloy steel casting products

Low Alloy Steel Casting Manufacturer & Exporter

KT-Foundry is a leading manufacturer and exporter of low alloy steel castings. Our expertise in advanced casting techniques ensures high-quality, durable components that meet the stringent requirements of various industries, including automotive, aerospace, and construction. With state-of-the-art facilities and skilled engineers, we deliver castings with enhanced strength, hardness, and corrosion resistance. Our commitment to precision and reliability makes KT-Foundry your trusted partner for low alloy steel castings.