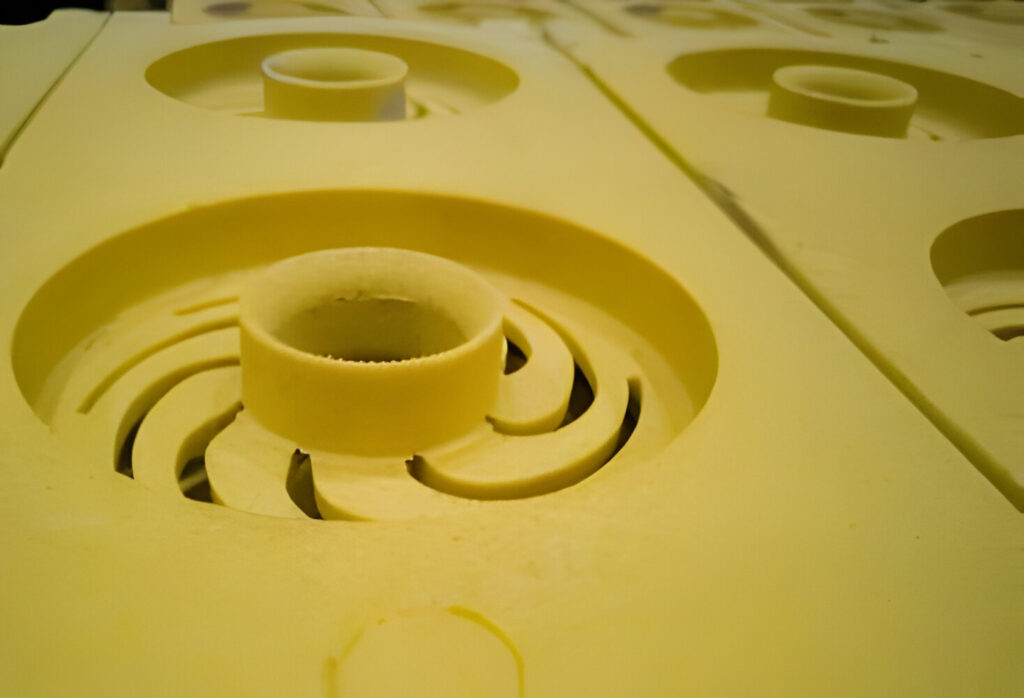

Impellers are the heart of centrifugal pumps, propelling fluids with precision and efficiency. Among the various methods to manufacture these critical components, sand casting emerges as a reliable and versatile technique, offering exceptional quality and cost-effectiveness. Let's explore the world of sand casting impellers and uncover why they are essential for diverse industries.

Versatility in Design and Material Selection

Sand casting impellers provide unparalleled flexibility in design and material selection. Whether it's a fuel pump impeller for automotive applications or a centrifugal pump impeller for industrial processes, sand casting allows for intricate geometries and a wide range of material options. This flexibility ensures that impellers can be tailored to meet specific performance requirements and environmental conditions.

Enhanced Performance and Durability

One of the key advantages of sand casting impellers is their ability to deliver enhanced performance and durability. Unlike other manufacturing methods, such as investment casting, sand casting offers superior mechanical properties, resulting in impellers that can withstand high pressures and temperatures without compromising performance. Whether it's a boat water pump impeller enduring harsh marine environments or a pool pump impeller resisting corrosion from chemical treatments, sand casting ensures longevity and reliability.

Cost-Effectiveness and Scalability

Sand casting impellers offer significant cost savings compared to alternative manufacturing methods. The simplicity of the sand casting process allows for rapid production cycles and minimal tooling costs, making it an ideal choice for both prototype development and high-volume production runs. Additionally, the scalability of sand casting enables manufacturers to meet varying demand levels efficiently, ensuring timely delivery of impellers to customers.

Quality Assurance and Consistency

At KT Foundry, we prioritize quality assurance throughout the sand casting process to ensure the consistency and reliability of our impellers. From material selection to final inspection, our experienced team adheres to stringent quality standards to deliver products that exceed customer expectations. Whether it's OEM well-casted impellers or custom-designed components, our commitment to quality ensures optimal performance and customer satisfaction.

Expertise and Innovation

With decades of experience in stainless steel casting and impeller manufacturing, KT Foundry stands as a leading provider of high-quality impellers for diverse applications. Our state-of-the-art facilities and skilled craftsmen enable us to push the boundaries of innovation, continuously improving our processes and products to meet the evolving needs of our customers.

In conclusion, sand casting impellers offer unmatched versatility, performance, and cost-effectiveness, making them indispensable components in various industries. Whether you require a stainless steel impeller casting for corrosive environments or a cast iron pump impeller for rugged applications, KT Foundry has the expertise and capabilities to deliver solutions that exceed your expectations. Contact us today to learn more about our sand casting impellers and how they can enhance the efficiency and durability of your pumping systems.