When it comes to the smooth operation of electric motors, every component plays a vital role, and one such crucial component is the electric motor bearing housing. In this article, we'll delve into the importance of electric motor bearing housings, their role in motor performance, and why choosing the right housing is essential for your machinery.

Understanding Electric Motor Bearing Housings

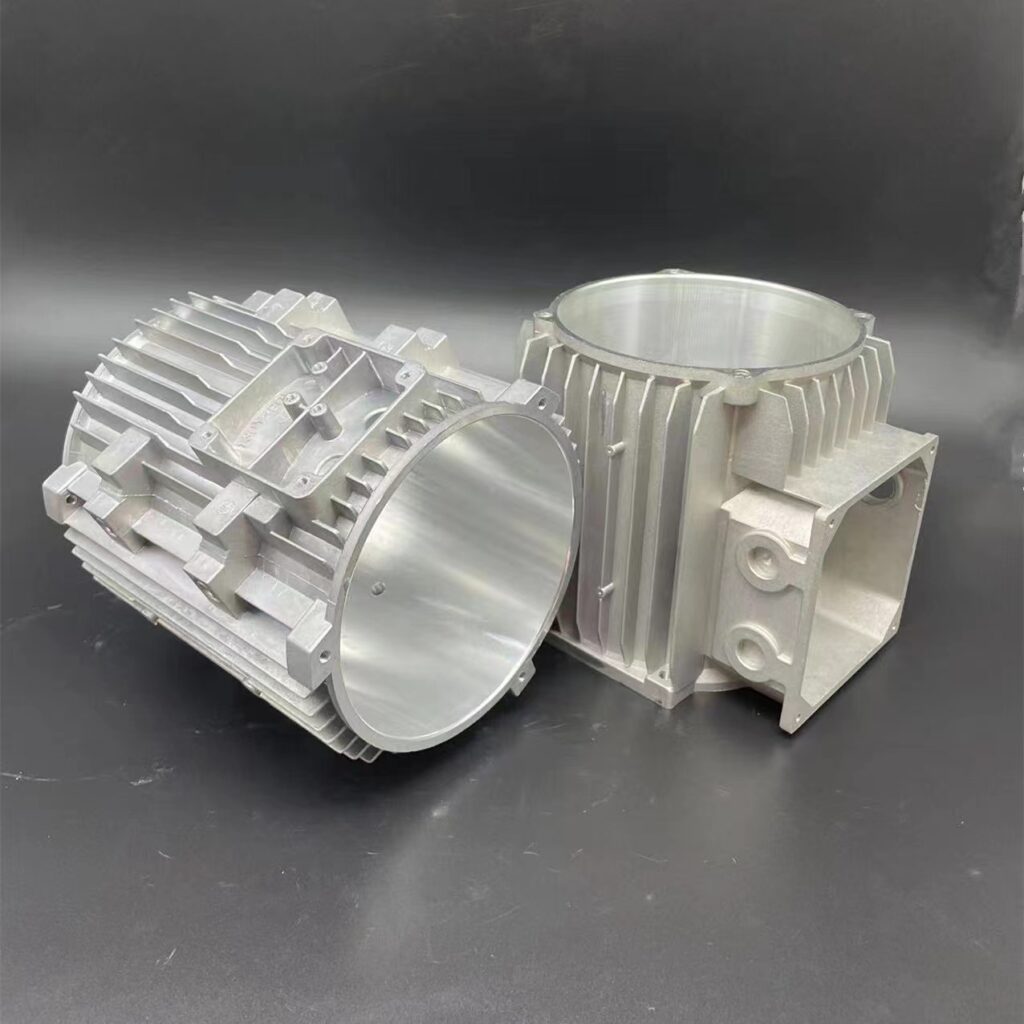

Electric motor bearing housings serve as the support and protection for the bearings within an electric motor. These housings are designed to house the bearings securely while providing them with adequate lubrication and protection from contaminants. They come in various shapes and sizes to accommodate different motor types and applications.

- Protection: One of the primary functions of an electric motor bearing housing is to shield the bearings from external elements such as dust, moisture, and debris. Without proper protection, bearings can wear out quickly, leading to motor failure and costly repairs.

- Support: Electric motor bearing housings provide a stable platform for the bearings to operate efficiently. They help distribute the load evenly across the bearings, preventing premature wear and ensuring smooth rotation.

- Lubrication: Many electric motor bearing housings are designed to facilitate the lubrication of the bearings, either through built-in lubrication channels or grease fittings. Proper lubrication is essential for reducing friction and heat generation, thereby extending the lifespan of the bearings and the motor as a whole.

Exploring Electric Motor Housing Variants

Motor housing casting is a commonly used manufacturing process for producing electric motor bearing housings. This process allows for the creation of intricate and precisely shaped housings that provide optimal support and protection for the bearings. Electric motor housings manufactured using casting techniques offer superior strength and durability compared to other manufacturing methods.

Innovations in Electric Motor Housing

Advancements in materials science have led to the development of electric motor bearing housings with enhanced properties. These housings are made from lightweight yet durable materials such as aluminum or composite alloys, offering improved performance and longevity compared to traditional steel housings.

Moreover, modern electric motor bearing housings are designed with efficiency in mind, incorporating features such as improved airflow and cooling to minimize heat buildup during operation. This not only extends the lifespan of the bearings but also enhances the overall efficiency of the motor.

Why Choose KT-Foundry for Your Electric Motor Bearing Housing Needs?

At KT-Foundry, we specialize in the design and manufacture of high-quality electric motor bearing housings for a wide range of applications. Our housings are precision-engineered to meet the exact specifications and requirements of our customers, ensuring optimal performance and reliability.

With years of experience in the industry, we have perfected our manufacturing processes to deliver bearing housings that are durable, efficient, and cost-effective. Whether you're in need of standard off-the-shelf housings or custom-designed solutions, you can trust KT-Foundry to provide you with the perfect housing for your electric motor bearings.

Contact Us Today!

Don't let subpar bearing housings compromise the performance and reliability of your electric motors. Upgrade to high-quality electric motor bearing housings from KT-Foundry and experience the difference firsthand. Visit our website to explore our complete range of products and get in touch with our team to discuss your requirements. Maximize the efficiency and lifespan of your motors with KT-Foundry bearing housings.