Pumps are key in the industrial world. They move liquids or gases from one place to another. A pump has three main parts: a housing, an impeller, and a motor. The housing holds everything together and keeps the fluid inside. The impeller has blades that spin to push the fluid through the pump. The motor makes the impeller turn, creating suction.

Designing pumps right is very important. It saves time and money, cuts downtime, boosts efficiency, and makes pump parts last longer. It also makes the workplace safer.

Key Takeaways

- Pumps are essential industrial equipment that play a crucial role in moving liquids or gases from one location to another.

- The three main parts of a pump are the housing, impeller, and motor.

- The pump housing serves as the mainframe, supporting the impeller and containing the pumped fluid.

- Proper pump design is essential for maximizing efficiency, minimizing downtime, and extending the lifespan of pump parts.

- Effective pump design can save time, money, and create a safer work environment.

Introduction to Pump Housing Parts

Pump housing parts are key to a pump's proper working and efficiency. Knowing about pump design is crucial. It affects pump performance, pump efficiency, pump maintenance, and pump safety.

A well-designed pump saves time, money, and resources. It cuts downtime, boosts efficiency, and makes parts last longer. It also makes the workplace safer. The pump type, fluid characteristics, and operating conditions all play a part in the best pump design.

Importance of Proper Pump Design

Having a good pump design is vital for many reasons:

- It makes sure the pump works well with the fluid and conditions, improving pump performance and pump efficiency.

- Well-designed pumps need less upkeep, cutting down on downtime and the costs of pump maintenance.

- Smart pump design leads to energy savings, boosting pump efficiency and sustainability.

- Good pump design focuses on safety, lowering accident risks and making the workplace safer.

Knowing how crucial proper pump design is helps pump operators and maintenance teams. They can make better choices to improve their pump systems' performance, efficiency, and safety.

"Effective pump design is the foundation for a reliable, efficient, and safe pump system."

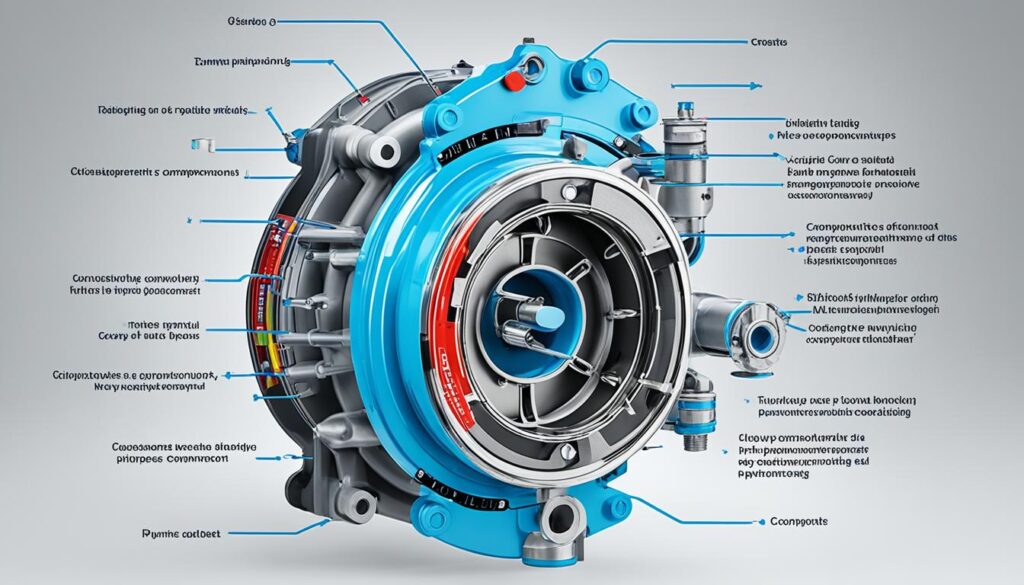

Key Components of Pump Housing

At the core of every pump is a vital part - the impeller. This device spins to push fluids through the system. The way it's made and shaped is key to how well a centrifugal pump or a positive displacement pump works.

Impellers: The Heart of a Pump

Impellers vary in shape and size for different uses and fluids. Their shape, size, and angle affect how much fluid they move, the pressure they create, and how much energy they use. Choosing and keeping the impeller right is key for a pump's dependability and success.

Other important parts of a pump include the shaft, casing, seals, bearings, couplings, and more. Each part is crucial for the pump's work, efficiency, and life span.

The design of the impeller is crucial. It affects how well the pump moves fluid and creates pressure. Whether it's for pushing fluid forward or not, the impeller is essential. It makes sure the fluid moves right and the pump works well.

"The impeller is the most critical component in a pump, responsible for generating the flow and pressure necessary for the application."

Choosing, setting up, and keeping the impeller and other parts right is vital. It keeps the whole pumping system reliable and efficient.

pump housing parts

The pump housing is key to a pumping system's success. It holds important parts that work together for efficiency and reliability. Knowing how each part works is key to keeping the pump running well.

At the core is the casing, the outer shell that holds everything inside. The shaft connects the motor to the moving parts, making the pump work. Sealing parts keep the inside safe from damage or getting too hot, helping the pump last longer.

Bearings make sure the shaft moves smoothly. Couplings link the motor and pump shaft, passing power without a hitch. The suction and discharge nozzles control the fluid flow. The check valve stops backflow, keeping the pump working right.

The strainer takes out solid bits from the fluid, protecting the pump's parts. This keeps the pump running well and makes it last longer. All these parts work together to keep the pump efficient and reliable.

"Proper maintenance and understanding of the pump housing parts are essential for ensuring the longevity and optimal performance of any pumping system."

Auxiliary Components and Their Importance

The pump's main parts like the impeller and volute are key to its function. But, there are also important auxiliary parts that help the pump work well and last longer. Bearings are a big deal among these parts. They let the shaft spin smoothly and move power to other parts.

Bearings: Smooth Operation

Pump bearings come in many types, each fitting different needs. You'll find roller bearings, ball bearings, Babbitt bearings, and sleeve bearings. Choosing and taking care of these pump bearings is key to a smooth pump. It also makes the pump more reliable.

Choosing the right bearing type depends on the load, speed, and where it's used. Roller bearings are great for high-speed, heavy loads. Ball bearings work well for lower loads. Babbitt bearings are good for older pumps because they handle shock loads and don't need extra lubrication.

Checking and maintaining the pump bearings often helps stop early wear and makes the pump last longer. Keeping the pump auxiliary components, like bearings, in good shape helps pumps work better and last longer.

"Proper bearing selection and maintenance are critical for ensuring the smooth and reliable operation of a pump."

Conclusion

The pump housing and its parts are key to a pump's success. Knowing how the impeller, shaft, casing, seals, and bearings work is crucial. This knowledge helps pumps work better, last longer, and use less energy. By choosing and looking after these pump housing parts well, we can make our pumps last longer, cut down on downtime, and make our workplaces safer.

Understanding pump design and keeping up with pump maintenance is vital for pump reliability. By taking good care of these pump housing parts, we can make our pump systems work their best. This leads to more productivity and profit in our industrial work.

As we keep innovating and using new technology, the pump housing and its parts will become even more important. By staying updated and proactive with pump housing parts, we can lead our businesses to success. This will help us stay ahead in the industrial equipment field.

FAQ

What are the main components of a pump housing?

A pump housing has several important parts. These include the impeller, shaft, casing, and sealing. Also, there are bearings, couplings, suction and discharge nozzles, a check valve, and a strainer.

Why is proper pump design crucial?

Good pump design is key for saving time and money. It helps reduce downtime, boosts efficiency, and makes pump parts last longer. It also makes the work area safer.

What are the different types of impellers used in pump design?

Pumps use different impellers like axial flow, radial flow, open, or closed types. The design of the impeller greatly affects how efficient and effective a pump is.

What is the purpose of the various components within the pump housing?

Each part of the pump housing has a specific role. The casing holds the internal parts in place. The shaft carries power from the motor. Sealing keeps the inside safe from the outside.

Bearings let the shaft turn smoothly. Couplings link the motor and pump shaft together. Nozzles manage the flow of fluid. Check valves stop backflow. Strainers take out solid particles.

What are the different types of bearings used in pump systems?

Pumps often use roller bearings, ball bearings, Babbit bearings, and sleeve bearings. Each type has its own benefits and fits best in certain situations.