In the realm of metal fabrication, the welding table is not merely a surface but a foundational tool that enhances precision, safety, and efficiency. Among the various materials used for welding tables, steel stands out for its robustness, durability, and versatility. This guide explores the essential aspects of steel welding tables, focusing on the best materials and designs, including practical applications and how to select the perfect table for your workshop needs.

Steel Material for Welding Tables: Strength and Suitability

Steel is predominantly favored for welding tables due to its excellent heat resistance and ability to withstand the rigors of welding operations. A 5/8 steel plate is often recommended for the table top owing to its thickness, which provides ample resistance against warping under high heat conditions. This thickness ensures a long-lasting flat surface, critical for accurate metalwork.

Design Variations and Features

Welding tables come in various designs tailored to specific needs and environments:

- Adjustable Steel Welding Table: These tables are designed with adjustability in height and angles, providing ergonomic comfort and flexibility, suitable for different welding tasks.

- Mobile Welded Steel Tables: Mobility adds versatility in large workshops. Equipped with heavy-duty casters, these tables can be moved easily around the shop floor, allowing for efficient use of workspace and flexibility in handling large projects.

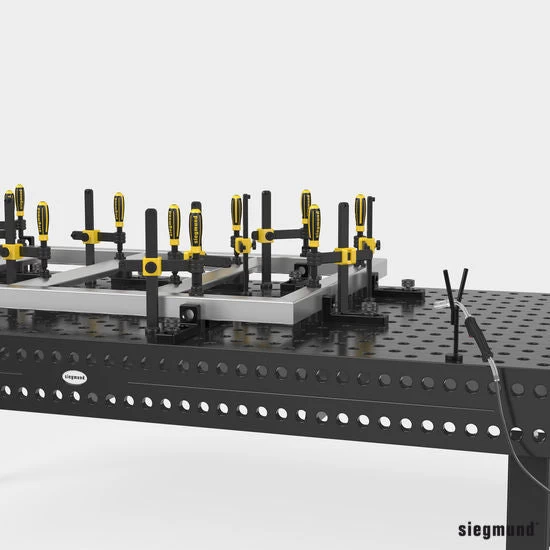

- Perforated Steel Plate for Welding Table: The perforated top is ideal for clamping and positioning workpieces in various configurations, enhancing the precision of welding jobs.

Practical Applications in Various Settings

Steel welding tables are indispensable in both industrial and smaller workshop settings. In automotive workshops, a robust steel table supports the repair of heavy components. In artistic metalworking, the precision offered by a flat bar welding table with a steel top is invaluable for creating intricate designs. The versatility of steel also makes it suitable for educational settings where durability and safety are paramount.

Customization and Enhancement

For those seeking specific functionalities, customization is key. V-shaped welded steel table leg sets provide stability and strength, essential for handling heavy materials. Welded steel table bases can be designed to include shelving and storage, optimizing the workspace.

Choosing the Right Steel Welding Table

When selecting a steel welding table, consider the following:

- Size and Thickness: Match the table size and top thickness to the types of projects you typically handle.

- Surface Type: Decide between a flat or perforated top based on your clamping and positioning needs.

- Mobility and Storage: Consider if mobility and additional storage are necessary for your workflow.

Invitation to Explore and Purchase

At kt-foundry, we offer a wide range of steel welding tables that cater to various needs, from adjustable and mobile models to custom designs tailored to your specifications. Visit our website to explore our products and find the perfect welding table that enhances your metalworking projects. Contact us today to discuss your requirements and how we can assist in selecting the right equipment for your needs.