When it comes to creating a precise and efficient welding workspace, the welding table hole size plays a crucial role. Selecting the appropriate hole size and spacing can significantly enhance the quality and convenience of your welding projects. This article delves into the essential aspects of welding table hole size, its benefits, and why investing in a perforated welding table with the correct hole pattern is essential for any welding professional.

Understanding Welding Table Hole Size and Its Importance

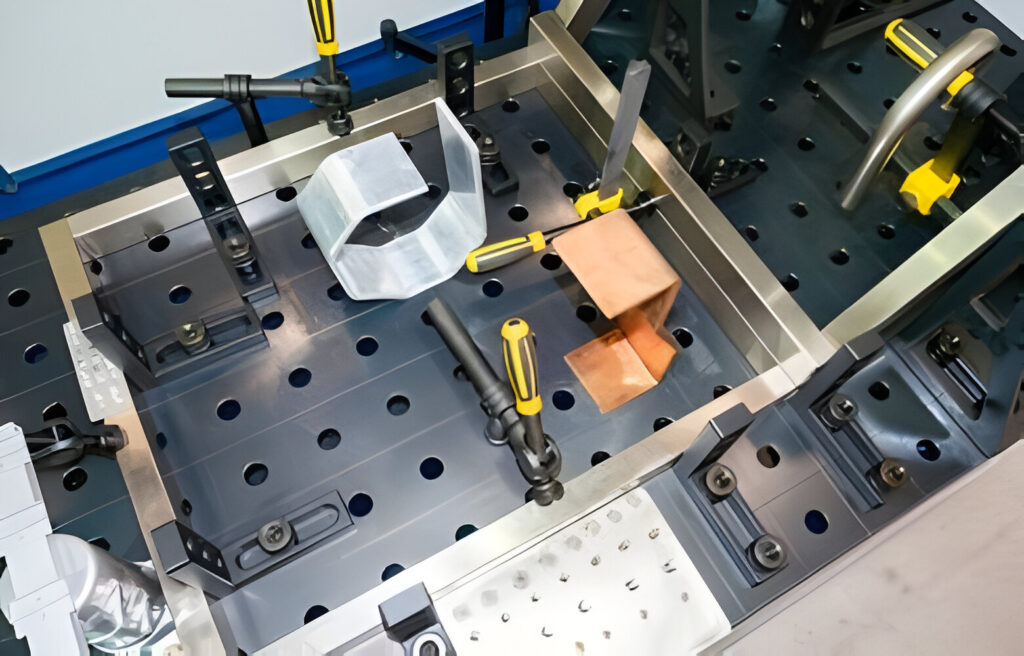

A welding table with holes is designed to facilitate secure and flexible clamping and fixturing. The holes, often in a grid pattern, allow welders to position their workpieces with greater precision. The standard hole size for most welding tables typically ranges from 16mm to 28mm, depending on the specific requirements of the projects.

Optimal Welding Table Hole Pattern and Spacing

The welding table hole pattern usually follows a grid layout, which ensures uniformity and ease of use. The common spacing between the holes can vary from 50mm to 100mm. This spacing is critical as it determines the ease of aligning and securing various workpieces. A well-designed welding table hole size and spacing will provide the versatility needed for complex and varied welding tasks.

Product Details: Perforated Welding Tables

At KT-Foundry, we offer a range of high-quality perforated welding tables designed to meet diverse welding needs. Our welding table top plates with holes are manufactured using robust materials to withstand the rigors of daily welding operations. The tables feature precisely machined holes that ensure perfect alignment and ease of use.

- Model A100 – Basic Welding Table

- Hole Size: 16mm

- Hole Spacing: 50mm

- Material: High-grade steel

- Features: Ideal for small to medium projects, easy to transport, and cost-effective.

- Model B200 – Professional Welding Table

- Hole Size: 20mm

- Hole Spacing: 75mm

- Material: Reinforced steel with anti-corrosion coating

- Features: Suitable for professional welders, provides excellent stability and versatility.

- Model C300 – Heavy-Duty Welding Table

- Hole Size: 28mm

- Hole Spacing: 100mm

- Material: Heavy-duty steel alloy

- Features: Designed for large-scale projects, exceptional durability, and load-bearing capacity.

Practical Applications and Scenarios

A welding table with holes is indispensable in various welding scenarios, from automotive repairs to industrial fabrications. The ability to secure workpieces quickly and accurately can save time and reduce errors, leading to more efficient workflow and higher-quality welds.

For instance, in automotive repair shops, a welding table top with holes allows mechanics to clamp and align components precisely, ensuring strong and reliable welds. In industrial settings, these tables are essential for fabricating large metal structures, providing the stability and flexibility required for complex assemblies.

Why Choose KT-Foundry’s Welding Tables?

At KT-Foundry, we understand the critical role of a well-designed welding table in achieving professional-grade results. Our tables are engineered with precision and built to last, ensuring you have a reliable workspace that enhances your welding capabilities.

Contact Us

Ready to elevate your welding projects with the perfect welding table? Visit KT-Foundry to explore our range of perforated welding tables and find the ideal solution for your needs. Our expert team is here to assist you in choosing the right product to enhance your welding precision and efficiency.