A perforated welding table is an essential tool for both amateur and professional welders. These tables are designed to enhance productivity and precision in welding tasks by offering a versatile and stable surface. In this guide, we'll explore the features, benefits, and applications of perforated welding tables, focusing on the significance of the welding table hole pattern, welding table hole size, and welding table hole spacing. We'll also introduce some top products available on the market to help you make an informed purchase decision.

Understanding Perforated Welding Tables

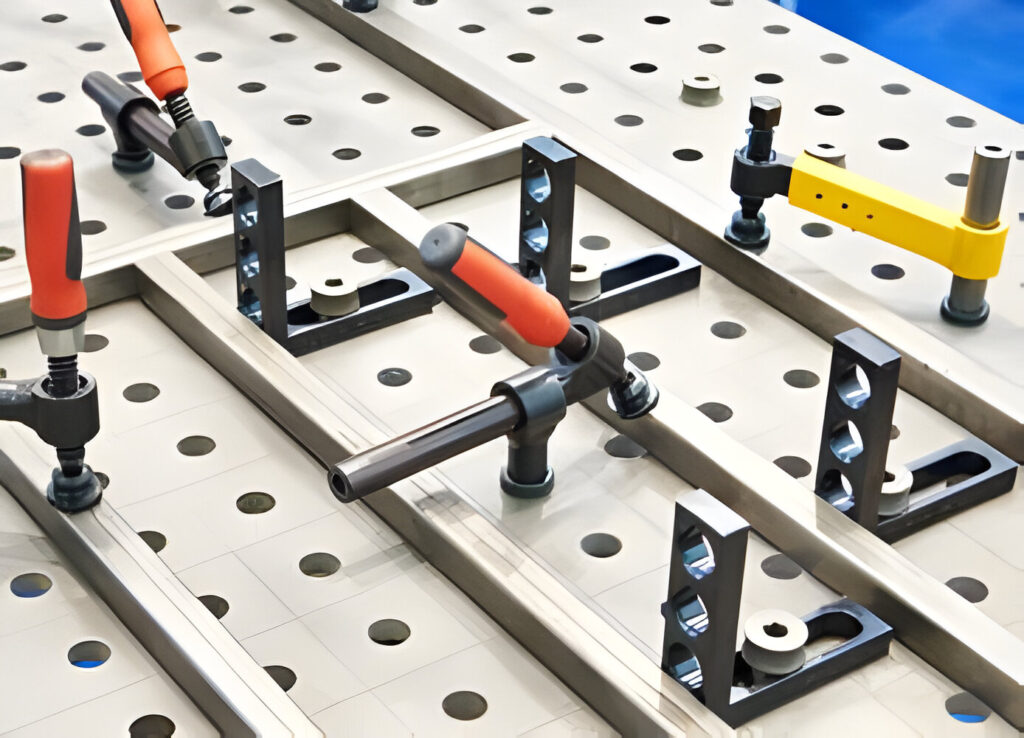

A perforated welding table, also known as a welding table with holes, features a top plate with evenly spaced holes. These holes allow for easy clamping and positioning of workpieces, providing a stable and flexible work surface. The perforated design is particularly beneficial for complex welding projects that require precise alignment and multiple clamping points.

Key Features and Specifications

- Welding Table Hole Pattern The hole pattern on a perforated welding table is typically arranged in a grid layout. This pattern ensures that clamps and fixtures can be positioned anywhere on the table, offering maximum versatility. The uniform distribution of holes also helps in evenly distributing the load, preventing warping and maintaining a flat working surface.

- Welding Table Hole Size The size of the holes on a welding table is crucial for compatibility with various clamping tools and accessories. Standard hole sizes range from 16mm to 28mm, with 16mm being the most common. Choosing the right hole size depends on the type of work you do and the accessories you plan to use. A larger hole size can accommodate more robust clamping systems, while smaller holes are suitable for finer work.

- Welding Table Hole Size and Spacing The spacing between the holes, known as hole spacing, is another important factor. Common spacing measurements are 50mm or 100mm. Closer spacing provides more flexibility in positioning clamps and fixtures, which is particularly useful for intricate welding projects. Wider spacing might be preferred for larger workpieces where fewer clamping points are needed.

Top Products and Applications

1. KT-Foundry Perforated Welding Table The KT-Foundry perforated welding table is designed for high precision and durability. It features a robust welding table top with holes arranged in a 50mm grid pattern, with 16mm diameter holes. This table is perfect for a variety of welding tasks, from small-scale projects to industrial applications. The high-quality steel construction ensures a flat and stable work surface, while the perforated design allows for versatile clamping options.

2. ProWeld Modular Welding Table The ProWeld modular welding table offers a customizable solution for professional welders. With a welding table plate with holes in a 100mm spacing pattern, this table is ideal for large and complex projects. The modular design allows for easy expansion and reconfiguration, making it a versatile addition to any workshop. The 28mm hole size accommodates heavy-duty clamps and fixtures, providing a secure and stable work environment.

Practical Application Scenarios

Automotive Fabrication In automotive fabrication, precision and stability are paramount. A perforated welding table provides the perfect platform for assembling and welding chassis components. The flexible clamping options allow for secure positioning of parts, ensuring accurate alignment and high-quality welds.

Metal Art and Sculpture For metal artists and sculptors, a welding table with holes offers the ability to work on intricate designs with ease. The adjustable clamping system allows for the secure positioning of various shapes and sizes, making it easier to create complex and detailed pieces.

Industrial Manufacturing In industrial manufacturing, the need for robust and reliable welding tables is critical. Perforated welding tables with larger hole sizes and spacing are ideal for handling heavy-duty projects. These tables provide the necessary stability and flexibility for assembling large structures and machinery components.

A perforated welding table is a versatile and indispensable tool for anyone involved in welding. Whether you're working on small-scale projects or large industrial tasks, the right table can significantly improve your productivity and precision. Consider the hole pattern, size, and spacing when choosing a welding table to ensure it meets your specific needs. Explore the high-quality options available at KT-Foundry and enhance your welding capabilities today.