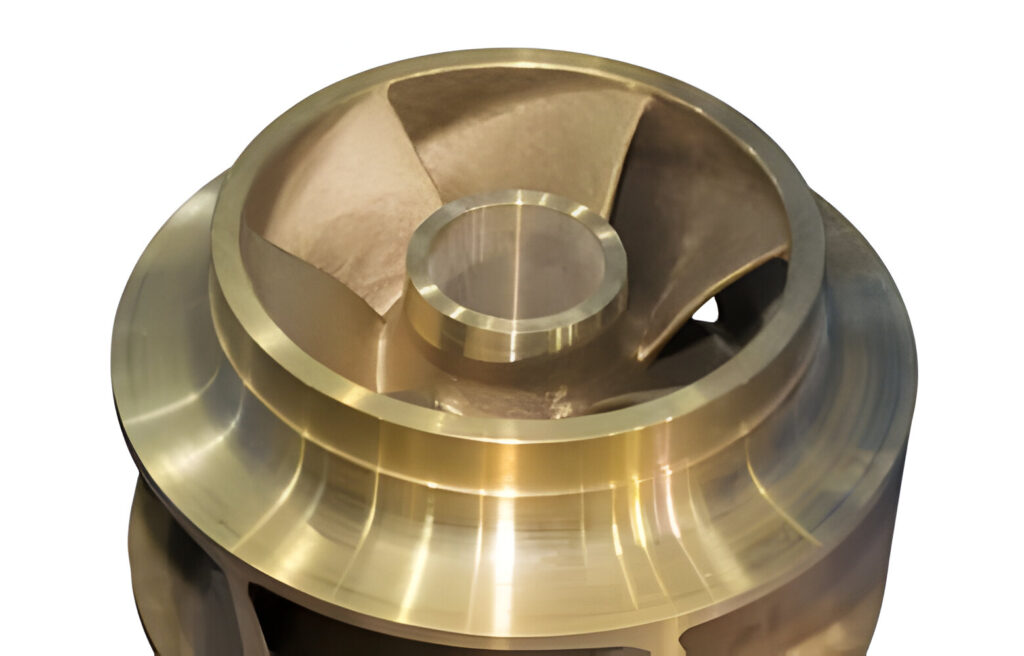

In the world of fluid dynamics and pump systems, the cast bronze impeller stands out as a critical component. These impellers are known for their durability, efficiency, and versatility across various applications. From water pumps to industrial machinery, cast bronze impellers play a pivotal role in ensuring the smooth and efficient operation of pumping systems. This article delves into the intricacies of cast bronze impellers, highlighting their manufacturing process, applications, and benefits, while subtly encouraging potential customers to contact us at kt-foundry for their impeller casting needs.

Manufacturing of Cast Bronze Impellers

The manufacturing process of cast bronze impellers involves several meticulous steps to ensure high quality and performance. The process begins with the selection of high-grade bronze alloys, known for their excellent resistance to corrosion and wear. The chosen alloy is melted in a furnace and poured into molds designed to shape the impeller.

- Molding: The molds used in impeller casting are crafted with precision to achieve the desired shape and dimensions. This step is crucial as it determines the final structure of the pump impeller casting.

- Casting: The molten bronze is carefully poured into the molds. This process must be handled with precision to avoid defects such as air bubbles or incomplete fills, which can compromise the integrity of the cast impeller.

- Finishing: Once the bronze has cooled and solidified, the cast impellers are removed from the molds and undergo finishing processes. These include trimming excess material, polishing, and sometimes additional treatments to enhance durability.

- Quality Control: Rigorous quality control measures are implemented to ensure each pump impeller meets the required standards. This includes inspecting for structural integrity, dimensional accuracy, and surface finish.

Applications and Benefits

Cast bronze impellers are widely used in various pump systems, including water pumps, industrial pumps, and marine applications. Their popularity is due to several key benefits:

- Durability and Longevity: Bronze impellers are highly resistant to corrosion and wear, making them ideal for applications involving water and other corrosive fluids. This durability translates to a longer lifespan and reduced maintenance costs.

- Efficiency: The design and material of bronze impellers contribute to efficient fluid movement, minimizing energy consumption and improving overall pump performance. This is particularly important in industrial settings where energy efficiency is a priority.

- Versatility: Cast bronze impellers can be customized to fit various pump designs and specifications. This flexibility allows manufacturers to produce impeller castings tailored to specific applications, ensuring optimal performance.

- Cost-Effectiveness: While bronze impellers may have a higher initial cost compared to other materials, their longevity and efficiency result in long-term cost savings. They are an investment that pays off over time.

Scenarios and Case Studies

Consider a municipal water treatment facility that relies on water pump impellers to maintain a steady supply of clean water to the community. The facility opted for cast bronze impellers due to their superior resistance to the corrosive chemicals used in water treatment processes. Over the years, the facility has experienced fewer pump failures and reduced maintenance costs, thanks to the reliability of the bronze impellers.

Similarly, in the marine industry, where saltwater corrosion is a significant concern, cast bronze impellers are preferred for their ability to withstand harsh conditions. Ships and offshore platforms equipped with these impellers benefit from uninterrupted operation and lower maintenance requirements.

Contact Us

At kt-foundry, we specialize in the production of high-quality impeller castings, including cast bronze impellers, cast iron impellers, and more. Our experienced team of impeller casting manufacturers ensures that each product meets the highest standards of quality and performance. Whether you need a pump impeller for a water treatment facility, industrial application, or marine environment, we have the expertise to deliver.

Visit our website at kt-foundry to learn more about our products and services. Contact us today to discuss your specific needs and receive a customized quote. Let us help you enhance the efficiency and reliability of your pump systems with our top-of-the-line impeller castings.