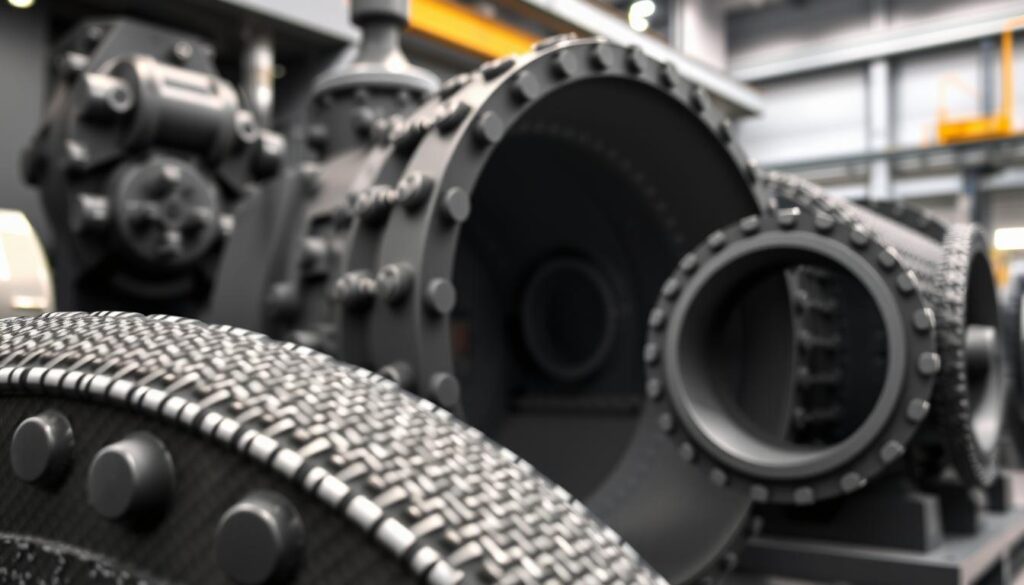

At KT Foundry, we specialize in manufacturing high-performance ball mill liners that are designed to optimize grinding efficiency and extend the lifespan of your equipment. Over the years, we’ve worked with numerous clients across the mining and cement industries, and one thing remains clear: the quality of your ball mill liners directly impacts your operational success. In this article, we’ll explore the top 5 benefits of using high-quality ball mill liners, and how our KT-ball mill liners can make a significant difference in your operations.

1. Improved Grinding Efficiencyn

One of the most critical benefits of high-quality ball mill liners is their ability to enhance grinding efficiency. Inferior liners can lead to uneven wear, reduced grinding media action, and ultimately, lower productivity.

Our KT-ball mill liners are engineered with precision to ensure optimal lifting and cascading of grinding media. This design maximizes the impact and friction between the media and the material, resulting in finer particle sizes and more efficient grinding. For example, one of our clients in the cement industry reported a 15% increase in grinding efficiency after switching to our liners, significantly reducing their energy consumption per ton of output.

To learn more about how our liner plates are designed for efficiency, visit our Liner Plate page.

2. Extended Equipment Lifespann

Ball mills are a significant investment, and their longevity is crucial for maintaining profitability. Low-quality liners can wear out quickly, leading to frequent downtime and costly replacements.

At KT Foundry, we use advanced materials and heat treatment processes to manufacture liners that are highly resistant to wear and impact. Our KT-ball mill liners are designed to withstand the harshest operating conditions, ensuring your equipment remains operational for longer periods.

A case in point is a mining company in South America that was experiencing liner failures every 6 months. After switching to our liners, they achieved a 30% longer lifespan, reducing their maintenance costs and downtime significantly.

3. Reduced Maintenance Costsn

Frequent liner replacements not only disrupt operations but also add to maintenance expenses. High-quality liners, like those we produce at KT Foundry, are built to last, reducing the frequency of replacements and associated labor costs.

Our liners are designed for easy installation and removal, further minimizing downtime during maintenance. Additionally, their superior wear resistance means fewer replacements over time, translating to substantial cost savings.

For instance, a gold mining operation in Africa reported a 20% reduction in annual maintenance costs after adopting our KT-ball mill liners. This was achieved through fewer liner replacements and reduced labor requirements.

Explore our range of durable liner solutions on our Liner Plate page.

4. Enhanced Safetyn

Safety is a top priority in any industrial operation. Poor-quality liners can crack or break under stress, posing serious safety risks to workers.

Our KT-ball mill liners are rigorously tested to ensure they can withstand extreme conditions without failing. This not only protects your equipment but also safeguards your workforce.

We recently collaborated with a copper mining company in Australia that was facing safety issues due to liner failures. After installing our liners, they reported zero safety incidents related to liner performance over a two-year period.

5. Customized Solutions for Specific Needsn

Every operation is unique, and a one-size-fits-all approach rarely delivers optimal results. At KT Foundry, we offer customized liner solutions tailored to your specific grinding requirements.

Whether you need liners for a small-scale operation or a large mining project, our team works closely with you to design liners that meet your exact needs. This includes selecting the right materials, profiles, and thicknesses to ensure maximum performance.

A recent example is a phosphate processing plant in the Middle East that required liners capable of handling highly abrasive materials. We developed a custom solution using high-chrome alloy, which resulted in a 25% improvement in wear resistance compared to their previous liners.

For more information on our custom liner solutions, visit our Liner Plate page.

Why Choose KT Foundry?n

With decades of experience in the industry, KT Foundry has established itself as a trusted name in ball mill liner manufacturing. Our commitment to quality, innovation, and customer satisfaction sets us apart.

Our KT-ball mill liners are used by some of the largest mining and cement companies worldwide, and our track record speaks for itself. From improved grinding efficiency to extended equipment lifespan, our liners deliver tangible benefits that drive operational success.

Conclusionn

Investing in high-quality ball mill liners is not just about improving performance—it’s about ensuring the long-term success of your operations. At KT Foundry, we’re proud to offer KT-ball mill liners that deliver unmatched durability, efficiency, and cost savings.

If you’re ready to take your grinding operations to the next level, we invite you to explore our products and services on our website: https://kt-foundry.com. Let us help you achieve your operational goals with liners you can trust.

By choosing KT-ball mill liners, you’re not just buying a product—you’re investing in a partnership dedicated to your success. Contact us today to learn more about how we can support your operations.