In the realm of fluid dynamics, the impeller stands as a pivotal component driving the efficiency and performance of various pumps. The demand for customized casting impellers is on the rise as industries seek tailored solutions to optimize fluid transfer processes. At KT-Foundry, we understand the significance of customization in achieving peak performance, and our range of customized casting impellers is designed to meet diverse application needs. Let's delve into the world of customized casting impellers and explore how they elevate pump efficiency to new heights.

Precision Engineering for Tailored Solutions

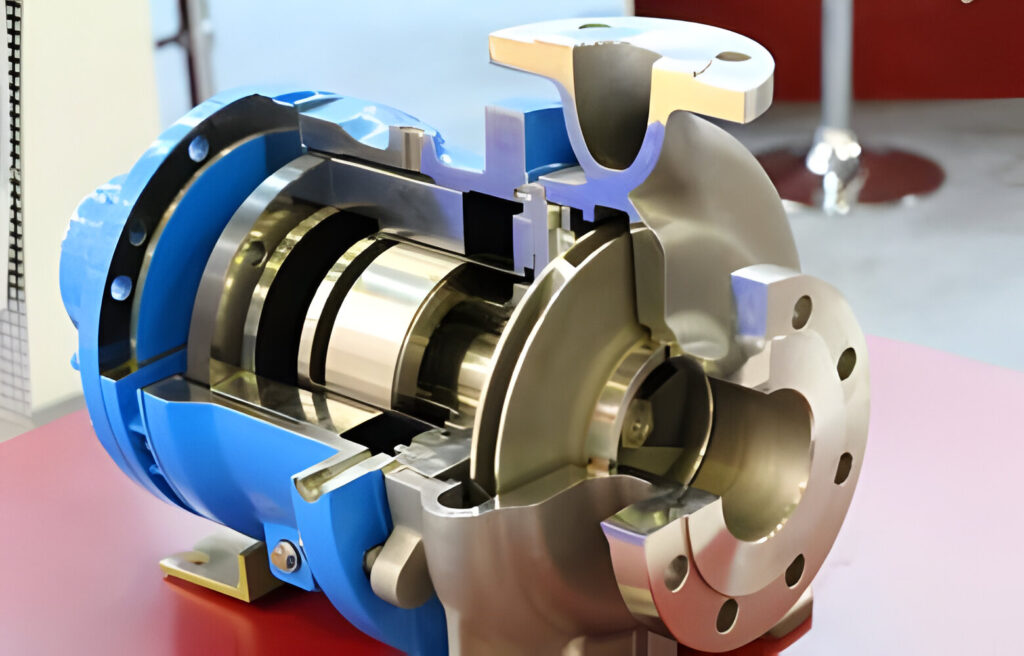

Customized casting impellers undergo a meticulous engineering process to ensure they meet the specific requirements of each application. Investment casting, renowned for its ability to produce intricate and complex shapes, is often utilized for crafting customized impellers. This process begins with the creation of a wax pattern, which is coated with a ceramic shell to form the mold. Molten metal, such as stainless steel or bronze, is then poured into the mold, resulting in a precisely shaped impeller upon solidification.

The customization options for casting impellers are virtually limitless, allowing for adjustments in blade geometry, impeller size, and material selection to optimize performance. Whether it's a fuel pump impeller for automotive applications or a centrifugal pump impeller for industrial processes, customized casting impellers ensure a perfect fit for each unique application.

Tailored Solutions for Diverse Applications

The versatility of customized casting impellers extends across a wide range of industries and applications:

- Automotive and Transportation: In the automotive sector, customized casting impellers play a crucial role in fuel pumps, water pumps, and cooling systems. Tailored designs ensure optimal fluid flow rates and pressure characteristics, contributing to the efficiency and reliability of vehicle systems.

- Industrial Processes: Industries such as manufacturing, mining, and wastewater treatment rely on customized casting impellers for fluid transfer and processing. Whether it's handling abrasive slurries or corrosive chemicals, customized impellers are engineered to withstand harsh operating conditions and deliver consistent performance.

- Marine Applications: Boat water pump impellers are vital for maintaining engine cooling and bilge pumping systems on marine vessels. Customized casting impellers ensure precise fitment and performance in marine environments, contributing to the safety and efficiency of maritime operations.

Advantages of Customized Casting Impellers

The benefits of opting for customized casting impellers are manifold:

- Optimized Performance: By tailoring impeller designs to specific application requirements, customized casting impellers offer superior performance and efficiency compared to off-the-shelf alternatives. The ability to fine-tune blade geometry and impeller size results in optimal fluid flow dynamics and energy efficiency.

- Enhanced Durability: Customized casting impellers are engineered to withstand the rigors of their intended application, ensuring long-term durability and reliability. By selecting appropriate materials and surface treatments, customized impellers can resist corrosion, erosion, and wear, prolonging their operational lifespan.

- Cost-Effective Solutions: While customization may entail additional upfront costs, the long-term benefits of improved performance and durability outweigh the initial investment. Customized casting impellers help minimize downtime, maintenance costs, and energy consumption, ultimately delivering cost savings over the product lifecycle.

Customized casting impellers offer a tailored approach to pump efficiency, providing precise solutions for diverse fluid transfer applications. At KT-Foundry, we specialize in crafting customized impellers that meet the unique requirements of each customer. From investment casting to precision engineering, our team is dedicated to delivering high-quality impellers that optimize pump performance and drive operational excellence. Contact us today to explore our range of customized casting impellers and unleash the full potential of your fluid transfer systems.