In the intricate world of pump technology, where precision and performance intersect, the impeller stands as a vital component. The impeller's role is fundamental, whether it's propelling water through a pool pump, fuel through an engine's fuel pump, or aiding in various other pumping applications. Within this realm, investment casting impellers have emerged as a beacon of efficiency and durability, revolutionizing the landscape of pump manufacturing.

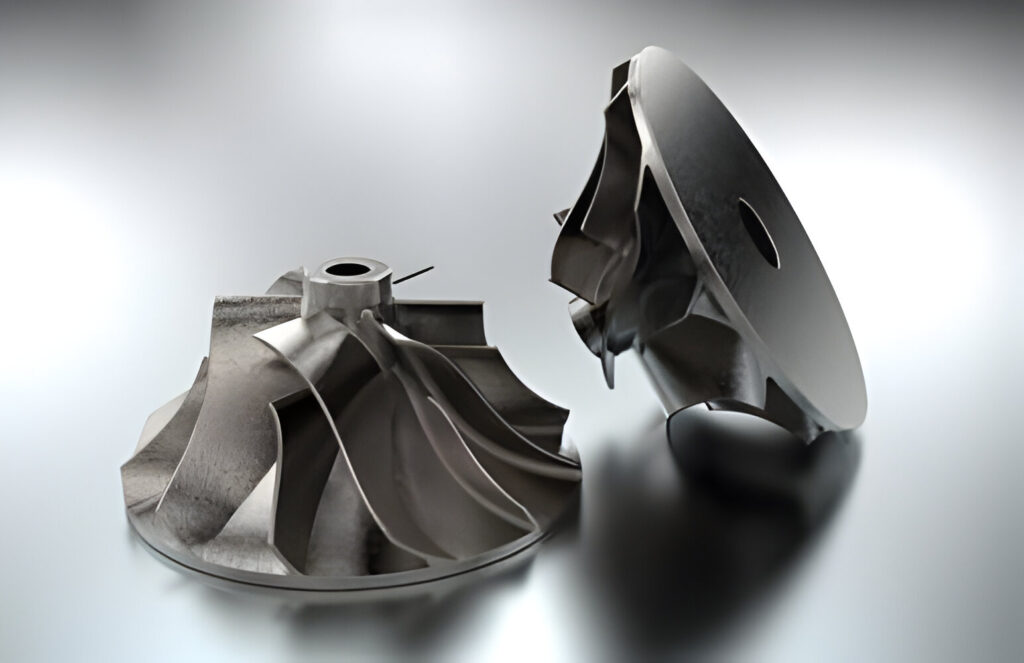

Investment casting, also known as lost-wax casting, is a meticulous process that allows for the creation of intricate and precisely detailed components. Unlike sand casting, which can produce rougher finishes and may be limited in complexity, investment casting offers unparalleled versatility. This method involves the creation of a wax pattern, which is then coated with a ceramic shell. Once the shell is set, the wax is melted away, leaving behind a hollow mold into which molten metal is poured, forming the final component.

Fuel pump impellers, essential for delivering fuel from the tank to the engine, benefit greatly from the precision afforded by investment casting. These impellers are subjected to high pressures and speeds, requiring exceptional durability and reliability. Investment casting ensures that fuel pump impellers are precisely engineered to withstand these conditions, minimizing the risk of failure and maximizing fuel efficiency.

Similarly, in centrifugal pump applications, where fluid is propelled by the rotation of the impeller, the choice of impeller material and manufacturing method is critical. Stainless steel impeller casting has gained traction in this space due to its corrosion resistance and strength. Centrifugal pump impellers manufactured through investment casting offer superior dimensional accuracy, leading to enhanced fluid dynamics and overall pump efficiency.

Boat water pump impellers, tasked with circulating coolant to prevent engine overheating, are another example of where investment casting shines. These impellers must operate reliably in harsh marine environments, facing exposure to saltwater and other corrosive elements. Investment casting ensures that boat water pump impellers are robustly constructed, capable of withstanding the rigors of marine use while maintaining optimal performance.

Pool pump impellers, crucial for maintaining water circulation and filtration in swimming pools, are also prime candidates for investment casting. These impellers must handle a range of debris and chemicals while maintaining efficient water flow. Investment casting allows for the creation of precisely engineered impellers with complex geometries, optimizing fluid dynamics and minimizing energy consumption.

At KT Foundry, we specialize in the manufacture of investment casting impellers for various pump applications. As a leading stainless steel castings manufacturer, we utilize state-of-the-art technology and stringent quality control measures to produce impellers that meet the highest standards of performance and durability. Our experienced team of engineers and technicians ensures that each impeller is meticulously crafted to exact specifications, providing our customers with reliable solutions for their pumping needs.

Whether you require OEM well-casted impellers, stainless steel impeller castings, or custom-designed impellers for specialized applications, KT Foundry has the expertise and capabilities to deliver. Contact us today through our website to learn more about our investment casting process and how our high-quality impellers can enhance the efficiency and reliability of your pumping systems.