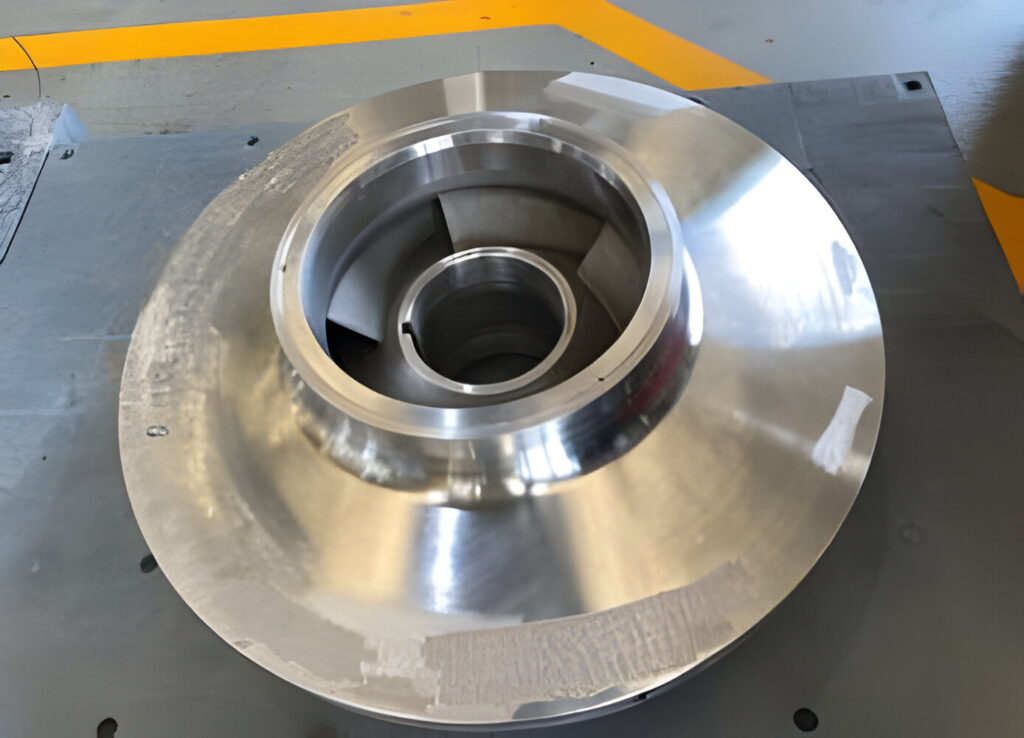

Cast iron pump impellers stand as stalwart components within fluid management systems, driving the flow of liquids with precision and reliability. Renowned for their durability and efficiency, these impellers play a vital role in various applications, ranging from centrifugal pumps to water pumps and beyond. Understanding the functionality and advantages of cast iron pump impellers sheds light on their significance in optimizing pumping operations across industries.

Strength and Durability of Cast Iron Pump Impellers

Cast iron, revered for its robustness and resilience, serves as an ideal material for pump impellers. The inherent strength of cast iron enables impellers to withstand high pressures and abrasive fluids without succumbing to wear and tear. This durability ensures prolonged service life and reduces the need for frequent replacements, making cast iron pump impellers a cost-effective choice for long-term use.

Moreover, the manufacturing process for cast iron impellers allows for intricate designs and complex geometries, optimizing fluid flow and efficiency within pump systems. Whether it's a centrifugal pump impeller or a boat water pump impeller, the robust construction of cast iron impellers ensures reliable performance in diverse operating conditions.

Efficiency in Fluid Dynamics with Cast Iron Pump Impellers

Efficiency lies at the core of pump performance, and cast iron impellers excel in promoting smooth fluid flow and minimizing energy consumption. Their precisely engineered designs and rugged construction contribute to reduced friction losses and improved hydraulic efficiency, translating into significant energy savings over time.

Furthermore, the thermal conductivity of cast iron facilitates efficient heat dissipation, preventing overheating and prolonging the lifespan of pump components. Whether it's a pool pump impeller or an OEM well-casted impeller, the reliability of cast iron ensures consistent performance and optimized fluid dynamics, enhancing overall pump efficiency.

Applications and Versatility of Cast Iron Pump Impellers

The versatility of cast iron pump impellers extends across a broad spectrum of applications, encompassing residential, commercial, and industrial sectors. From fuel pump impellers to pool pump impellers, cast iron components cater to diverse pumping needs with unparalleled strength and efficiency.

In addition to their performance benefits, cast iron pump impellers offer compatibility with various fluids, including water, chemicals, and fuels, making them suitable for a wide range of pumping environments. Whether it's a sand casting impeller for rugged applications or an investment casting impeller for precision tasks, cast iron ensures reliable performance and longevity in demanding operating conditions.

Elevating Pump Performance with Cast Iron Pump Impellers

In conclusion, cast iron pump impellers stand as indispensable components within fluid management systems, offering strength, durability, and efficiency in equal measure. As a leading manufacturer of cast iron pump impellers, KT-Foundry is committed to delivering high-quality components that meet the rigorous demands of modern pumping operations.

Unlock the potential of your pump systems today by partnering with KT-Foundry for all your cast iron pump impeller needs. With expertise in impeller casting processes and a dedication to customer satisfaction, we empower businesses to enhance their fluid management systems with confidence and reliability.