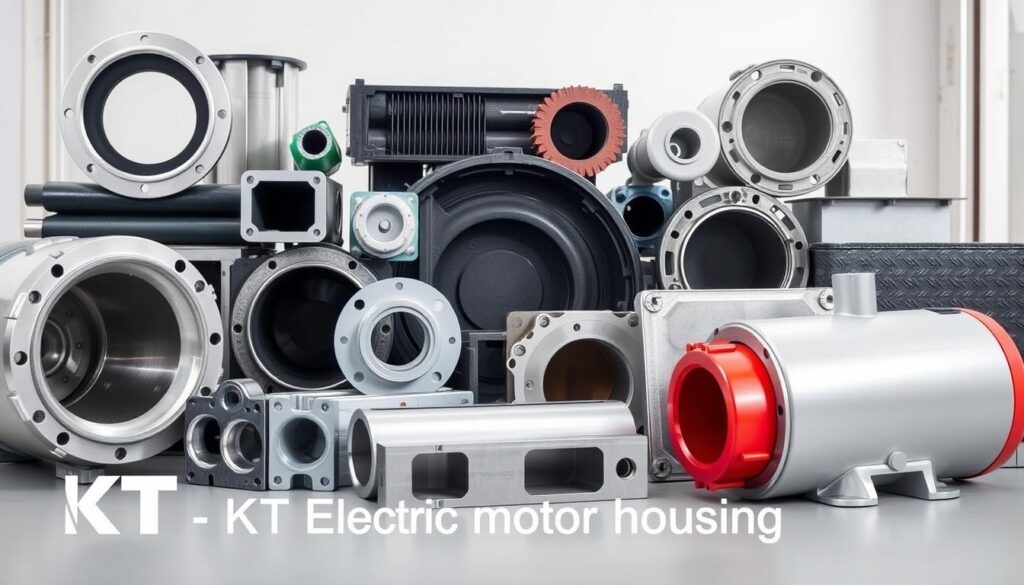

As the world relies more on electric motors, the role of electric motor housing is vital. These parts protect the motor's inside, improve its performance, and extend its life. At KT Foundry, we focus on making top-notch electric motor housings for many uses.

We use aluminum die casting and other advanced materials to create innovative motor housings. Our solutions offer strong protection, efficient cooling, and precise engineering. Whether you need TEFC housings, ODP housings, explosion-proof, or waterproof designs, or even custom and modular ones, we can help.

Key Takeaways

- Aluminum alloy is the most used material for electric motor housings. It's great for machining, strong, durable, and recyclable.

- High-quality electric motor housings need precision, leak-proof design, compact size, and wear resistance. These features ensure stable operation and a longer service life.

- KT Foundry is an expert in aluminum die casting for electric motor housings. We provide solutions for various industries, including electric vehicles, industrial manufacturing, and HVAC systems.

- The right material and design for electric motor housings are key. They help convert electrical power to mechanical rotation, reduce thermal buildup, and improve performance and reliability.

- Customization and modularity in electric motor housing design offer tailored solutions. They meet specific needs, like compact size, efficient thermal management, and enhanced durability.

Introduction to Electric Motor Housing

At the heart of every electric motor is the electric motor housing. This protective shell is key to keeping the motor's parts safe. It guards the rotor, stator, bearings, and windings, ensuring they work well and last long.

What is Electric Motor Housing?

The electric motor housing is the outer cover that protects the motor's inner parts. Made from materials like aluminum, cast iron, and stainless steel, it's built to last. It keeps the motor safe from dust, moisture, and vibrations, and helps it cool down efficiently.

Importance of Motor Housing in Electric Motor Systems

The motor housing is very important for the motor's performance and reliability. It keeps the motor's parts in good shape, reducing vibrations and controlling the environment. This makes the motor last longer, work better, and be more affordable and durable.

"The electric motor housing is the unsung hero of electric motor systems, safeguarding the critical components and ensuring the long-term reliability and efficiency of the entire assembly."

The electric motor industry is always changing, and so is the need for better motor housing. Companies like KT Foundry lead the way with their wide range of high-quality and cost-effective motor housing options.

Types of Electric Motor Housing

Electric motor housings come in many designs to fit different needs. From TEFC to ODP and explosion-proof, each has its own benefits. They help motors work well and last longer.

Totally Enclosed Fan-Cooled (TEFC) Housings

TEFC housings keep motors safe from dust and dirt. They also have fans to cool the motor. This makes the motor last longer.

These housings are great for places like factories and mines. They protect motors from harsh conditions.

Open Drip Proof (ODP) Housings

ODP housings are for cleaner, drier places. They let some air in to cool the motor. But they don't protect as well as TEFC housings.

ODP motors are good for HVAC systems and pumps. They are more affordable and compact.

Explosion-Proof and Waterproof Housings

For dangerous or wet areas, you need explosion-proof and waterproof housings. They can handle high pressure and keep motors safe from water. These are key in industries like chemicals and mining.

Custom and Modular Housings

Custom and modular housings are made for special needs. They fit unique motor sizes and shapes. This ensures they work well in specific systems.

These are used in unique machines and medical devices. They can't be found in stores, so they're made to order.

Materials Used in Electric Motor Housing

Electric motor housings are made from many materials. Each one has its own benefits for different uses. From light aluminum alloys to strong cast iron and stainless steel, the right material is key for electric motors to work well and last long.

Aluminum: Lightweight and Efficient

Aluminum alloy is often chosen for motor housings. It's light and good at cooling down motors. This keeps the motor running at the best temperature. Plus, aluminum is easy to work with, making it a cost-effective choice.

Cast Iron: Heavy-Duty and Durable

Cast iron is great for tough jobs. It's strong and lasts a long time, perfect for places like factories and mines. Its solidness also helps keep the motor parts in line, reducing vibration.

Stainless Steel: Corrosion-Resistant Options

In places where rust is a problem, like near the sea or in chemical plants, stainless steel is a good choice. It resists corrosion, keeping the motor working well for a long time. Though it costs more, stainless steel is worth it for its protection.

Composite and Plastic Housings for Specialized Applications

For special needs, like being very light or flexible, composite or plastic housings are used. These materials can be made to fit specific needs, like being small or quiet. Though not as common as metal, they open up new design possibilities.

| Material | Key Characteristics | Typical Applications |

|---|---|---|

| Aluminum Alloy | Lightweight, efficient heat dissipation, easy machinability | General-purpose electric motors, HVAC systems, automotive applications |

| Cast Iron | Heavy-duty, durable, robust mechanical strength | Industrial motors, heavy-duty machinery, mining equipment |

| Stainless Steel | Corrosion-resistant, long-lasting, high-end applications | Motors used in harsh environments, chemical processing, marine applications |

| Composite/Plastic | Lightweight, cost-effective, design flexibility | Specialized applications, compact motors, noise-sensitive environments |

Choosing the right material for electric motor housing is important. It affects the motor's weight, strength, cost, and how it works in different places. Knowing the benefits of each material helps manufacturers pick the best one for their motors.

Application Areas of Electric Motor Housing

Electric motor housings are key parts in many areas. They help electric motors work well and efficiently. They are used in everything from electric cars to heavy machinery, showing their wide use.

Electric Vehicles: Lightweight Housings for Improved Efficiency

In the electric car world, lightweight aluminum motor housings are vital. They help these cars go further and use less energy. This makes electric cars better for the environment and more efficient.

Industrial Use: Heavy-Duty Motors for Manufacturing and Mining

Places like factories and mines need strong motor housings. Cast iron or stainless steel housings are perfect for these tough spots. They keep heavy motors running smoothly, powering important machines.

HVAC Systems: Motor Housing for Pumps, Compressors, and Fans

HVAC systems need electric motors for pumps, compressors, and fans. The motor housings must be quiet and good at cooling. This keeps the HVAC system working well and saving energy.

Medical Devices: Compact and Quiet Electric Motor Housing Solutions

In medicine, motor housings are important for devices like surgical tools and rehab gear. They are made to be small, quiet, and strong. This ensures medical devices work safely and reliably, helping both patients and doctors.

Working with a top electric motor housing maker like KT Foundry can help a lot. They offer expert advice and custom solutions for your needs.

Choosing the Right Manufacturer for Your Needs

When picking a manufacturer for your electric motor housing needs, consider several factors. Look for a provider with deep experience in your industry. They should offer customized solutions that fit your application needs. Check their manufacturing skills, quality control, and customer service for a smooth partnership.

A good manufacturer should have a history of making high-quality electric motor housings. KT Foundry is an example. They use advanced techniques and materials to make durable, affordable solutions.

Make sure the manufacturer can work with different materials like aluminum, cast iron, and stainless steel. Also, check their quality control, such as strict inspections and certifications. This ensures their products are reliable and consistent.

"At KT Foundry, we take pride in our ability to manufacture high-quality electric motor housings that meet the diverse needs of our customers. Our commitment to innovation and customer satisfaction is at the core of everything we do."

When choosing a manufacturer, look at their production capabilities. Check if they can handle custom orders, prototype development, and quick turnaround times. A flexible provider can meet your unique needs and adapt to market changes.

Choosing the right manufacturer for your electric motor housing needs requires a thorough evaluation. Look at their expertise, resources, and focus on customers. Partnering with a reputable provider ensures your electric motor systems will last long, work efficiently, and perform well.

Conclusion: Choosing the Right Electric Motor Housing

Factors to Consider: Environment, Cost, and Performance

When picking the right electric motor housing, think about the environment, cost, and how well it performs. The housing's material, design, and how it's made should match the motor's use. This includes things like temperature, humidity, and exposure to chemicals or abrasives.

It's important to find a balance between the initial cost and the housing's long-term value. This ensures we get the best deal for our money.

The electric motor housing must protect, cool, and work precisely to improve the motor's performance and life. By looking at environment, cost, and performance, we can pick the right housing. This meets our specific needs and offers reliable, efficient, and lasting operation.

Talking to a trusted maker like KT Foundry can help us find the best housing for our electric motor systems.

FAQ

What is the most common material used for electric motor housings?

Aluminum alloy is the top choice for electric motor housings. It's easy to work with, strong, and looks good. It's also durable, can be recycled, and has a high strength-to-weight ratio.

What are the key features of Reigstone's motor housings?

Reigstone's motor housings are known for their tight tolerances and no leaks. They have a compact design and are resistant to wear. These features help the motor work smoothly and last longer.

What is the main purpose of the electric motor housing?

The electric motor housing protects the motor's parts like the rotor and stator. It keeps them safe from damage and helps cool them down. It also makes sure the motor works well by keeping its parts in the right place.

What are the different types of electric motor housings?

There are many types of electric motor housings. You can find TEFC, ODP, explosion-proof, waterproof, and custom designs. Each type is made for specific needs.

What are the common materials used for electric motor housings?

Motor housings are made from materials like aluminum, cast iron, stainless steel, and plastics. Aluminum is light and good at cooling. Cast iron is strong, stainless steel resists corrosion, and plastics are versatile.

In what applications are electric motor housings used?

Electric motor housings are used in many places. They're in electric cars, industrial motors, HVAC systems, and even in medical tools like surgical equipment.

What factors should be considered when choosing a manufacturer for electric motor housings?

When picking a manufacturer, look at their materials, production, quality control, and service. Choose someone with experience in your field and who can make custom solutions.

What factors should be considered when selecting the right electric motor housing?

Think about the environment, cost, and performance needs. The housing should match the motor's conditions, like temperature and chemicals. It's important to find a balance between cost and durability to get the best value.