At KT-Foundry, we know how crucial ball mill liners are for ball mills in the mining world. They come in materials like rubber, rubber composite, and metal alloys. Each is made for specific mining and processing needs.

Our advanced ball mill liner solutions aim to boost production and safety. We use top-notch software and inspection data to create custom liners. These liners improve grinding, cut down on maintenance, and make your ball mill last longer.

Looking to increase your output, lower noise, or enhance ball mill performance? Our wide range of liners offers the protection and boosts you need. Stay ahead in the competitive mineral processing field with our help.

Understanding Ball Mill Liners and Their Role in Mining Operations

Ball mill liners are key to mining success. They protect the mill shell and boost grinding efficiency. These liners are vital for the mill's performance.

Protection and Performance Enhancement

Ball mill liners shield the mill shell from grinding media and material impact. This reduces wear and tear, extending the mill's life. It also cuts down on downtime and maintenance costs.

The liners' design affects grinding media movement. This creates the best conditions for grinding and processing materials.

Material Processing Fundamentals

The liners' design and material affect grinding media and material interaction. This impacts size reduction, throughput, and efficiency. Proper liner selection and maintenance boost milling performance.

Impact on Grinding Efficiency

Liners are crucial for grinding efficiency. Well-designed liners improve grinding media movement. This leads to faster size reduction and higher throughput.

Operators can improve milling efficiency by focusing on liners. This enhances productivity and profitability.

| Key Factors | Impact on Ball Mill Operations |

|---|---|

| Mill Shell Protection | Extends equipment lifespan, reduces downtime and maintenance costs |

| Grinding Media Motion | Optimizes material processing conditions, enhances grinding efficiency |

| Throughput and Energy Efficiency | Increases productivity, reduces power consumption, and lowers operating costs |

"Proper selection and maintenance of ball mill liners can significantly impact the milling process, reducing power consumption and increasing throughput."

Types of Ball Mill Liners Available Today

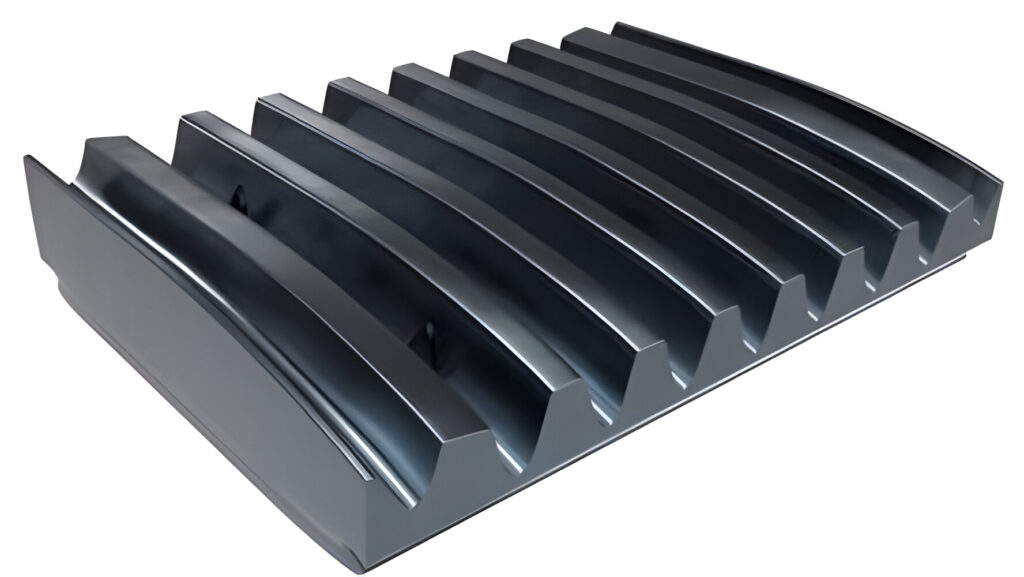

Ball mills need strong liners to handle the impact and wear from grinding media. There are many types of liners, including rubber liners, metal liners, and composite liners. These combine rubber and metal for extra protection.

Metal liners, like manganese steel or cast iron, are very strong and last long. They are used in many mills to protect the shell from wear and damage.

Rubber liners are lighter than steel, making them easy to install by hand. They also help prevent the grate plates from getting clogged, which boosts mining efficiency.

Composite liners mix rubber and metal for a balance of benefits. They offer good wear resistance, impact protection, and sealing. These liners can also reduce noise and prevent mineral lock-up, making work conditions better.

| Liner Type | Key Features | Advantages |

|---|---|---|

| Rubber Liners | Lightweight, effective grate plate protection | Ease of installation, improved throughput |

| Metal Liners (Manganese Steel, Cast Iron) | Exceptional strength and durability, wear resistance | Versatile, long-lasting performance in milling equipment |

| Composite Liners | Combines rubber and metal, sealing properties | Balanced wear resistance, impact protection, noise reduction |

These liners are made with parts like shell plates, lifter bars, head plates, grate plates, and pulp lifters. They help improve milling and grinding efficiency. By choosing the right liner for the mill size and material, engineers can get better performance and longer equipment life.

Key Benefits and Features of Ball Mill Liners

Ball mill liners are key in mining, boosting productivity and saving costs. They are tough, offering abrasion resistance and impact resistance. This protects the mill's inside from grinding wear and tear.

These liners also cut down on noise levels in the workplace. This makes the environment safer and more comfortable for workers. Plus, their design and materials can make the equipment last longer, cutting down on maintenance needs.

Ball mill liners help make grinding more efficient and reduce downtime. This makes mineral processing operations more cost-effective. The right liners are essential for less maintenance and reliable ball mill performance.

Top companies in ball mill liner tech keep innovating. They create custom liners to boost productivity, safety, and save costs for mining operations.

Essential Components and Installation Considerations

Proper liner installation and maintenance are key for ball mills in mining. It's important to size, align, and fasten liners correctly. Many makers offer liner handler tools and services for safe, efficient mill reline jobs.

Keeping an eye on liners and replacing them when needed is vital. It keeps the mill running well and stops damage. A good liner installation and maintenance support plan cuts down on downtime. It also boosts the mining process's overall performance.

- Proper sizing and alignment of liner components for optimal performance

- Utilization of specialized equipment, such as liner handlers, to ensure safe and efficient liner replacement

- Regular monitoring and timely replacement of worn liners to maintain grinding efficiency and prevent mill shell damage

- Manufacturer-provided installation services and maintenance support for optimal liner performance

"Careful installation and maintenance of ball mill liners are essential to maximize the efficiency and longevity of mining equipment."

Focus on the liner installation process and a solid maintenance support plan. Mining operations can then boost their productivity, cut downtime, and keep ball mills running well for a long time.

Conclusion

Ball mill liners are key in the mining world. They protect equipment, boost grinding efficiency, and cut costs. At KT-Foundry, we create custom liners for our mining clients. This ensures they work well and last long.

Choosing the right liner material and keeping them in good shape can really help mining operations. Our solutions use the latest in materials and design to improve mineral processing. This leads to better grinding efficiency.

Need solid, grid, rubber, or magnetic liners? Our team at KT-Foundry is ready to help. We tailor our solutions to meet your mining needs. Working with us can make your ball mills more efficient and profitable.

KT-Foundry

Bring Your Designs to Reality– Experience Custom Perfection with On-Demand Casting!