Electric motors are the backbone of countless industries, powering everything from household appliances to industrial machinery. Within these motors lies a crucial component that often goes unnoticed but plays a pivotal role in their performance and longevity – the motor housing. In this article, we delve into the realm of motor housings, exploring their importance, various types, and the benefits they offer to industries worldwide.

Motor Housing: The Unsung Hero of Electric Motors

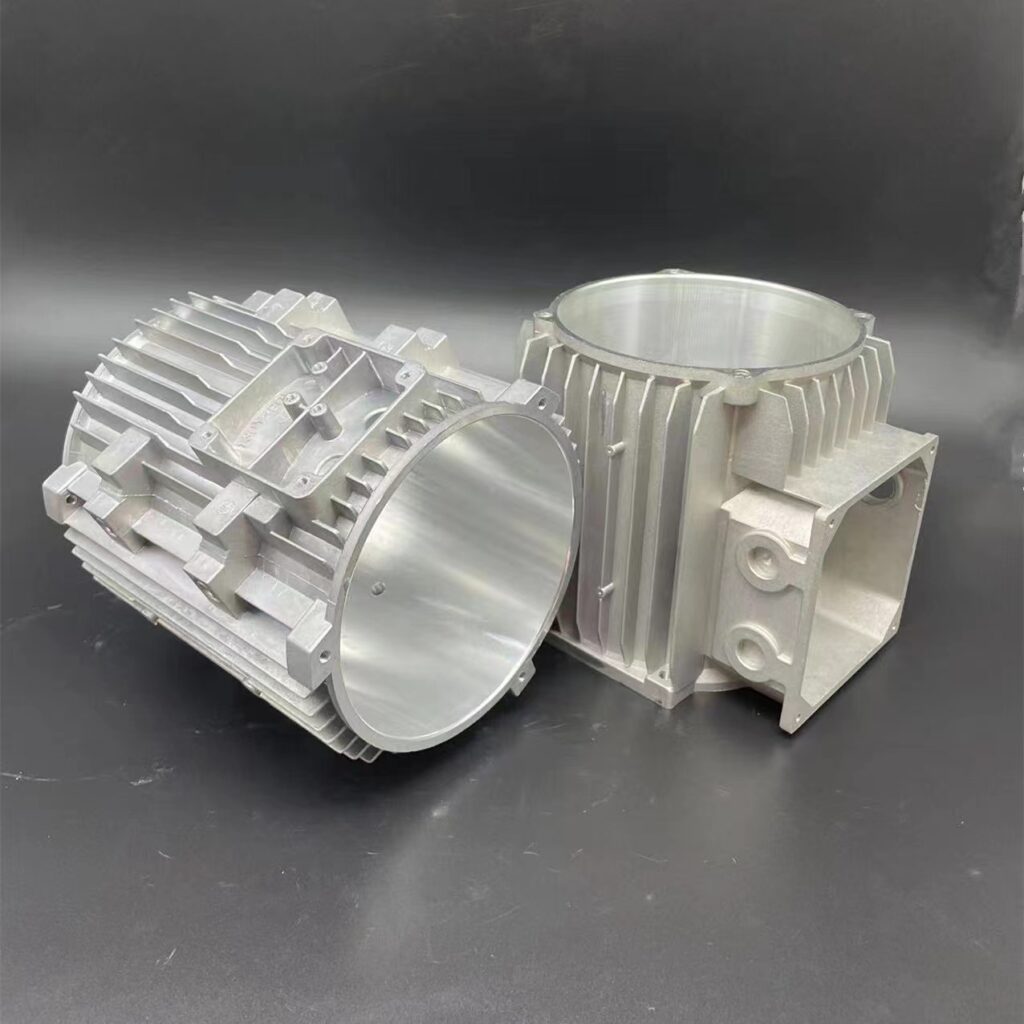

The motor housing, also known as the motor casing or electric motor casing, is the protective enclosure that houses the internal components of an electric motor. While it may seem like a simple covering, its role is multifaceted. Firstly, it provides structural support, protecting the delicate internal components from external damage and environmental factors such as dust, moisture, and debris. Additionally, it helps dissipate heat generated during operation, preventing overheating and ensuring optimal performance.

Types of Motor Housings and Their Applications

Motor housings come in various shapes, sizes, and materials, each tailored to specific applications and environments. Here are some common types:

- Motor Housing Parts: These include components such as end bells, bearing housings, and terminal boxes, which are essential for assembling and enclosing the motor.

- Motor Housing Casting: Cast iron and aluminum are commonly used materials for motor housing casting due to their durability and heat dissipation properties. Cast housings are ideal for applications requiring robustness and resistance to harsh conditions.

- Electric Motor Housing: Made from materials like plastic, steel, or aluminum, electric motor housings offer a lightweight yet durable solution for a wide range of applications, including appliances, automotive systems, and HVAC equipment.

Benefits of Quality Motor Housings

Investing in high-quality motor housings can yield numerous benefits for industries and consumers alike:

- Enhanced Efficiency: Well-designed motor housings facilitate efficient heat dissipation, allowing the motor to operate at optimal temperatures and minimizing energy loss.

- Extended Lifespan: By protecting internal components from contaminants and mechanical stress, sturdy motor housings contribute to the longevity of electric motors, reducing downtime and maintenance costs.

- Improved Safety: Enclosed motor housings prevent accidental contact with live electrical parts, reducing the risk of electrical hazards and ensuring a safer working environment.

- Customization Options: Manufacturers offer a variety of customization options for motor housings, including size, shape, mounting provisions, and ingress protection ratings, allowing customers to tailor the housing to their specific requirements.

Contact Us for Your Motor Housing Needs

At KT Foundry, we specialize in the production of high-quality motor housings and casting solutions to meet the diverse needs of our customers. With years of experience and expertise in the field, we understand the importance of reliable motor enclosures in ensuring the performance and longevity of electric motors across various industries.

Whether you require standard motor housing parts or custom-designed enclosures, our team of skilled engineers and technicians is committed to delivering superior products that exceed your expectations. Visit our website to explore our comprehensive range of motor housing solutions and contact us today to discuss your specific requirements. Let us be your trusted partner in enhancing the efficiency and durability of your electric motors.