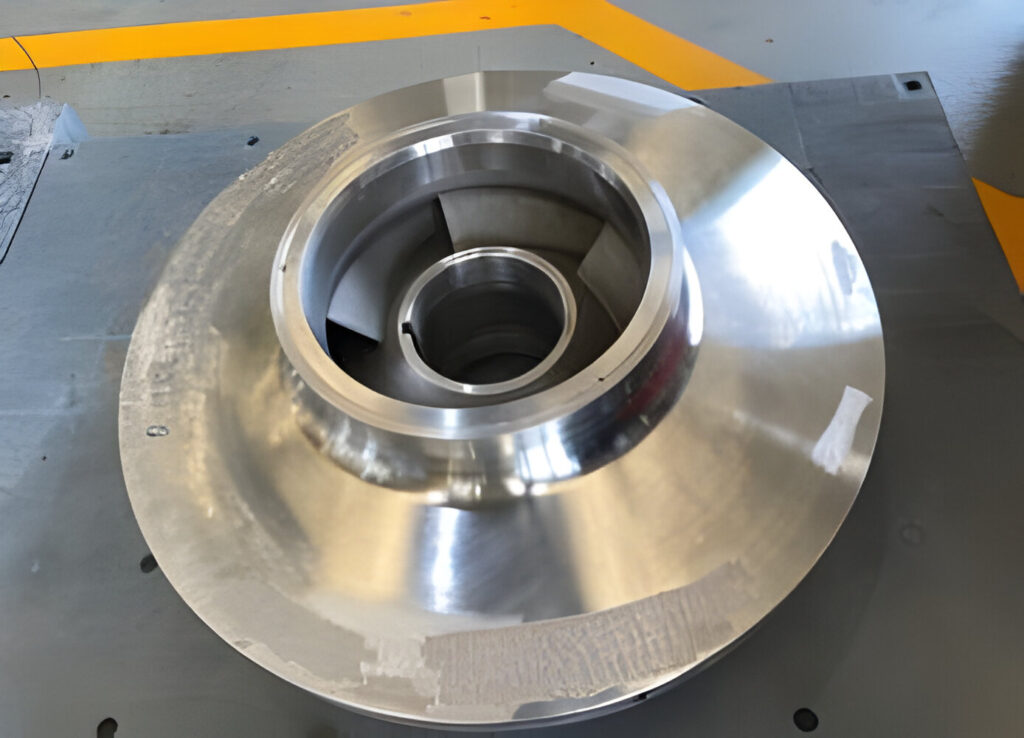

In the realm of fluid mechanics and machinery, the impeller serves as the heart of many pumping systems. From centrifugal pumps to fuel pumps and water pumps, the efficiency and reliability of these devices often hinge on the quality and design of their impellers. Among the various materials utilized for impeller construction, stainless steel casting has emerged as a favored choice for its durability, corrosion resistance, and versatility.

Stainless steel casting is a precision manufacturing process that involves pouring molten stainless steel into a mold to produce intricate shapes with exceptional dimensional accuracy. This method offers several advantages over alternative techniques such as sand casting or investment casting, particularly when it comes to producing impellers for critical applications like vacuum pumps.

At the forefront of this technology, stainless steel casting manufacturers like KT Foundry specialize in crafting high-quality impellers that meet stringent performance requirements. Whether it's for OEM applications or aftermarket replacements, stainless steel impellers offer unmatched durability and performance in demanding environments.

One of the key advantages of stainless steel impeller casting is its ability to withstand corrosive substances commonly found in industrial and marine environments. Unlike traditional cast iron impellers or bronze alternatives, stainless steel resists rust and degradation, ensuring long-term reliability even in harsh conditions.

Moreover, stainless steel impellers excel in applications where hygiene and cleanliness are paramount, such as food processing or pharmaceutical industries. Their non-porous surface inhibits bacterial growth and facilitates easy cleaning, making them ideal for maintaining stringent sanitary standards.

In the realm of vacuum pump impellers, stainless steel casting plays a crucial role in optimizing performance and efficiency. Vacuum pumps rely on the precise movement of impeller blades to create suction and evacuate air or other gases from a system. The superior strength and dimensional stability of stainless steel impellers ensure smooth operation and minimal wear, resulting in extended service life and reduced maintenance costs.

Furthermore, the versatility of stainless steel casting allows for intricate impeller designs tailored to specific pump requirements. Whether it's optimizing flow characteristics, minimizing cavitation, or enhancing overall efficiency, custom-engineered impellers offer unparalleled performance benefits.

Understanding the nuances of impeller design and manufacturing processes is essential for optimizing pump performance. Stainless steel casting manufacturers employ advanced techniques such as computer-aided design (CAD) and finite element analysis (FEA) to refine impeller geometries and ensure optimal fluid dynamics.

When comparing different impeller materials, the choice between stainless steel, cast iron, or bronze often comes down to specific application requirements. While cast iron impellers may offer cost advantages, they lack the corrosion resistance and longevity of stainless steel counterparts. Similarly, bronze impellers exhibit excellent corrosion resistance but may not withstand abrasive environments as effectively as stainless steel.

In the context of pump impellers, the material selection directly impacts overall system performance and longevity. Stainless steel casting provides a balance of strength, corrosion resistance, and machinability, making it the preferred choice for a wide range of pumping applications.

Whether it's a centrifugal pump impeller for industrial processes, a boat water pump impeller for marine applications, or a pool pump impeller for recreational facilities, stainless steel casting delivers unmatched performance and reliability.

In conclusion, stainless steel casting revolutionizes the design and manufacturing of pump impellers, offering superior performance, durability, and corrosion resistance. As a leading stainless steel castings manufacturer, KT Foundry combines expertise with innovation to deliver premium-quality impellers tailored to diverse application needs. Contact us today to learn more about our stainless steel impeller casting solutions and elevate your pumping systems to new heights of efficiency and reliability.