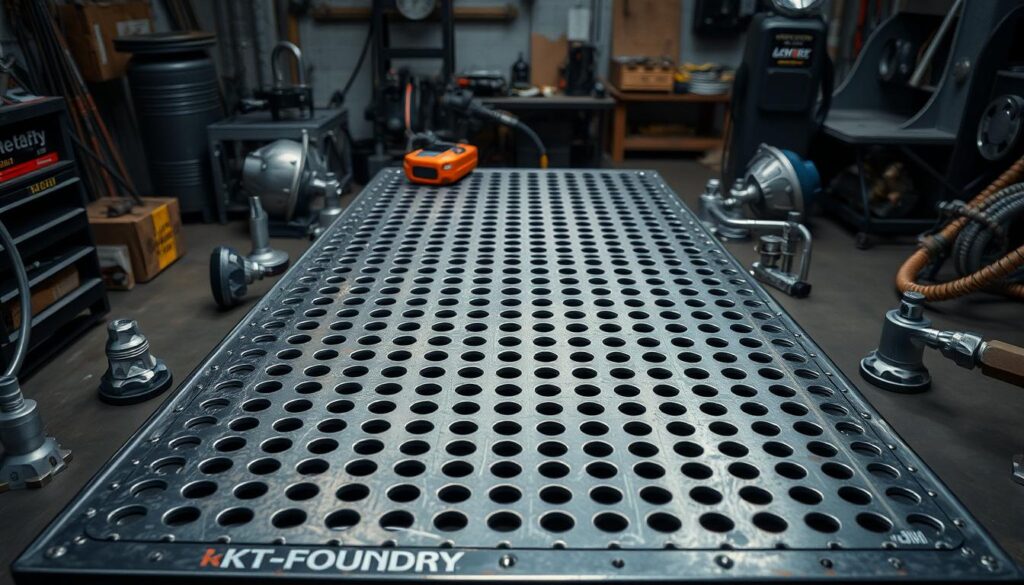

For metal fabricators and welders, having a versatile and efficient workstation is key. Welding tables with a grid hole pattern change our work areas into places that handle many tasks. These tables have holes of the same size, making them flexible and boosting our productivity and welding skills.

The grid hole pattern on welding tables helps us clamp and position our work with precision. This means we get accurate and consistent welds. It opens up many possibilities, fitting our welding stations for various projects like automotive, aerospace, or general metal work.

Whether we use portable, adjustable, or modular welding stations, the grid hole pattern makes them more versatile. By choosing top-notch welding tables with this feature, we make the most of our tools and accessories. Our workspaces become centers of productivity.

Key Takeaways

- Welding tables with a grid hole pattern offer enhanced versatility for metal fabricators and welders.

- The strategic arrangement of uniform-sized holes allows for secure clamping and positioning of work pieces, enabling greater flexibility and efficiency in the welding process.

- The grid hole pattern design transforms a standard welding table into a multi-functional workstation, unlocking a wide range of possibilities for customization and workspace optimization.

- These welding tables are commonly used in various industries, such as automotive manufacturing, aerospace, and general metal fabrication shops.

- Investing in high-quality welding tables with a grid hole pattern can significantly enhance overall productivity and the welding experience.

The Benefits of a Grid Hole Pattern on Your Welding Tables

The grid hole pattern on welding tables changes the game. It brings many benefits that make welding better. From versatility to precise alignment, it's a big deal.

Versatility in Clamping and Fixture Positioning

The grid hole pattern makes clamping and positioning easy. Welders can keep work pieces in the right spot without making special jigs. This saves time and makes welding more efficient.

Micrometer Precision for Alignment

The grid pattern is a big win for welders. It ensures work pieces are placed just right. You can make tiny adjustments for perfect welding alignment.

For metal work, repairs, prototypes, or production welding, the grid hole pattern is key. It lets you use your welding setup fully. This boosts your work's precision and efficiency.

Choosing the Right Grid Hole Pattern for Your Welding Tables

Customers can pick from the K16 and K28 grid hole patterns for welding tables. Each has its own benefits. The k16 welding table has 16mm holes, 50mm apart. This is a versatile and affordable choice for many welding tasks.

The k28 pattern comes in standard and diagonal layouts. The standard has 100mm centers, and the diagonal has 50mm centers. This gives more flexibility and precision for complex projects. The choice depends on the project's size, complexity, and the need for customization and accessories.

K16 Welding Table Grid Pattern: 16mm Holes at 50mm Centers

The K16 grid is a practical and cost-effective choice for many welding tasks. It has 16mm holes, 50mm apart. This mix of hole size and spacing meets the needs of most welding projects.

K28 Welding Table Grid Patterns: Standard and Diagonal Options

For tougher projects, the k28 grid offers more flexibility and precision. The standard K28 has 28mm holes at 100mm centers. The diagonal layout has 50mm spacing, perfect for intricate clamping and positioning.

"The choice between these options depends on the specific needs of the user, such as the size and complexity of the work pieces, as well as the desired level of customization and accessibility to compatible accessories."

Conclusion: Unlock the Full Potential of Your Welding Tables

Welding tables become more versatile and efficient with a strategic grid hole pattern. These holes help in secure clamping and precise positioning. This makes it easy to adapt your workspace for different projects.

Choosing between the K16 or K28 system depends on your needs. Both offer the flexibility and precision to boost productivity. By optimizing your welding tables with these accessories, you open up new possibilities in your metal fabrication workshop.

Investing in the right welding table customization can change your workspace for the better. It takes your welding table accessories to a new level of efficiency and flexibility. Embrace the power of a grid hole pattern to unlock your welding tables' true potential today.

FAQ

What are the benefits of a grid hole pattern on welding tables?

A grid hole pattern on welding tables offers many advantages. It makes clamping and positioning easier and more precise. It also ensures accurate alignment during welding.

How does the grid hole pattern improve clamping and fixture positioning?

The grid system makes clamping and positioning work easy. Welders can hold work pieces in the best position for their projects. This saves time and boosts efficiency.

What are the different grid hole pattern configurations available for welding tables?

There are two main options: K16 and K28. The K16 has 16mm holes spaced 50mm apart. The K28 comes in standard and diagonal layouts for more flexibility and precision.

How do the different grid hole pattern configurations compare in terms of versatility and customization?

The choice between K16 and K28 depends on your project needs. The K16 is versatile and cost-effective. The K28 offers more flexibility and precision for complex projects.

How can a grid hole pattern transform a standard welding table into a multi-functional workstation?

Grid holes make clamping and positioning precise and secure. This lets users easily adapt their workspace for different projects. It turns a basic welding table into a versatile workstation.