The landscape of motor manufacturing is undergoing a transformation with the increasing adoption of aluminum housings in various motor applications. This change is prominently observed in industries ranging from automotive to aerospace, where the demand for lightweight, durable, and efficient motor solutions is paramount. This article explores the various facets of aluminum motor housing, focusing on its benefits, applications, and the manufacturing processes employed by leading factories.

Introduction to Aluminum Motor Housing

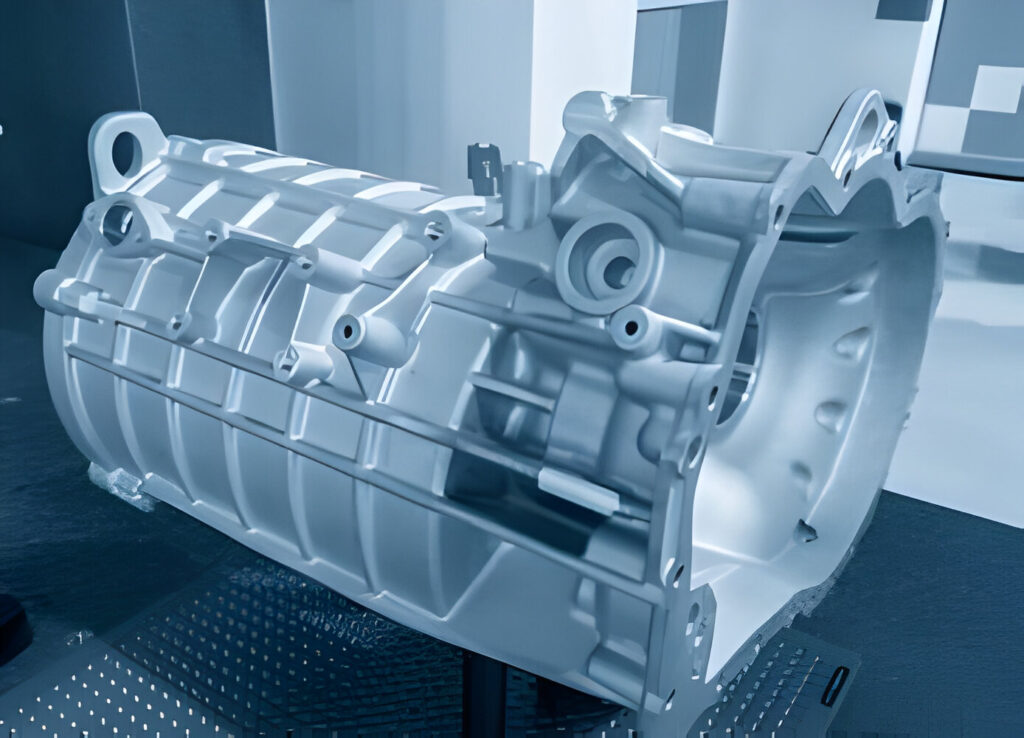

Aluminum motor housing refers to the protective casing of a motor made from aluminum or its alloys. This component is crucial as it protects the internal parts of the motor from environmental factors and physical damage while aiding in heat dissipation. The popularity of aluminum for motor housing lies in its excellent strength-to-weight ratio, corrosion resistance, and superior thermal conductivity compared to other metals.

Manufacturing Processes

The most common method used for producing aluminum motor housing is die casting, specifically aluminum die casting housing techniques. This process involves injecting molonium aluminum under high pressure into a steel mold or die. The precision of die casting allows for complex shapes and high dimensional accuracy, making it ideal for manufacturing motor casing and motor housing parts that require minimal machining and finishing. Factkies specializing in this process, like KT Foundry, utilize state-of-the-art machinery and stringent quality control measures to ensure that each product meets the highest standards of quality and performance.

Applications and Scenarios

Aluminum housing is extensively used in the manufacturing of various types of motors, including servo motors and electric motors. Servo motor housing, often made from aluminum, is essential in robotics, CNC machinery, and automated manufacturing lines where precision movement is critical. Similarly, electric motor housings are integral to household appliances, electric vehicles, and industrial equipment. The lightweight nature of aluminum contributes to enhanced energy efficiency and performance in these applications.

Frequently Asked Questions (FAQs)

- Why choose aluminum for motor housing?

- Aluminum is preferred for its lightweight, corrosion resistance, and excellent thermal management properties, which enhance the overall efficiency and lifespan of the motor.

- Can aluminum motor housing be customized?

- Yes, facilities like KT Foundry offer customization options for aluminum die cast housing, enabling adaptations to customer-specific requirements regarding size, shape, and features.

- What is the advantage of die cast aluminum housing over other types?

- Die casting provides superior dimensional accuracy, allows for the integration of complex features, and achieves a smoother surface finish, reducing the need for additional processing.

Encouragement to Engage

For those interested in exploring the vast possibilities of aluminum motor housing and other related products, KT Foundry offers a comprehensive range of solutions tailored to meet the most demanding industrial requirements. We invite potential customers to visit our website at [kt-foundry] to learn more about our capabilities and how we can assist in enhancing your motor applications. Our expert team is ready to support your needs with advanced solutions and premium quality products.