In the world of precision engineering and manufacturing, the development of motor housings represents a critical step towards enhancing the reliability and efficiency of various motor applications. Aluminum, known for its lightweight and robust properties, has become a pivotal material in this sector. Among the various methods employed to produce these vital components, die casting stands out for its precision, efficiency, and cost-effectiveness.

Aluminum Motor Housing and Die Casting

Aluminum motor housings are essential in numerous industries, including automotive, aerospace, and electronics. These housings serve as protective shells for motor assemblies, shielding sensitive components from environmental hazards and mechanical stress. Utilizing aluminum not only reduces the weight but also improves the heat dissipation capabilities of motor housings, which is crucial for maintaining optimal performance.

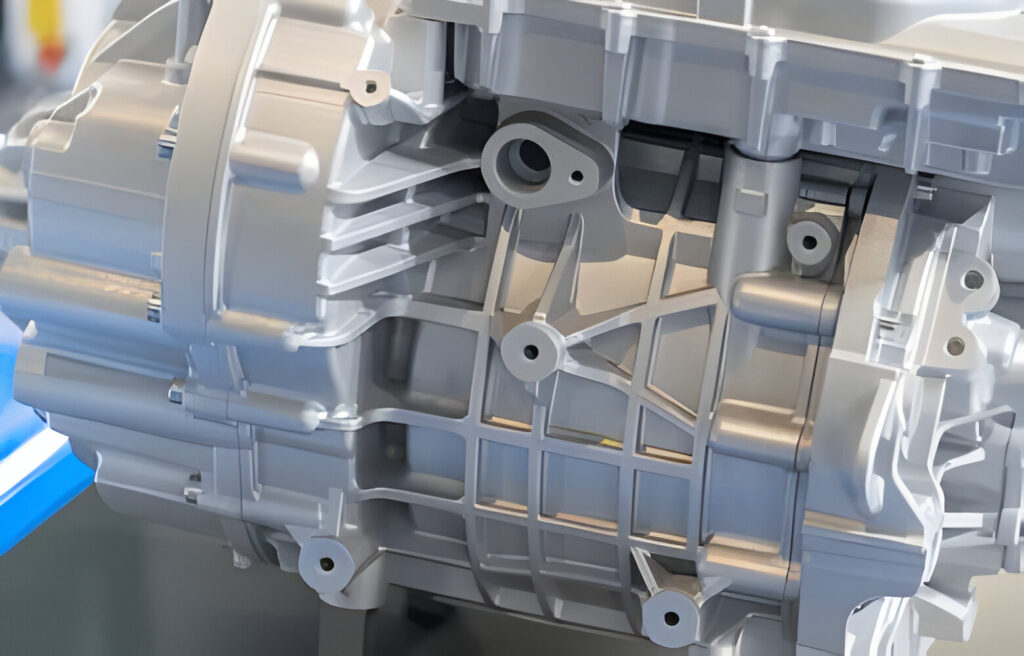

Die casting aluminum for motor housings involves injecting molten aluminum into a steel mold at high pressure. This method allows for high volume production of parts with excellent dimensional accuracy and smooth surface finishes. Die cast aluminum housings are predominantly favored for their strength and thermal conductivity, making them ideal for high-performance applications such as in servo motors and electric vehicles.

Product Spotlight: Die Cast Aluminum Housing for Servo Motors

Our state-of-the-art servo motor housings are designed to meet the exacting demands of precision and performance. These housings are manufactured using advanced aluminum die casting techniques that ensure superior durability and fit. Ideal for applications requiring high torque and precision, our servo motor housings enhance the overall efficiency of the system while providing robust protection against external impacts.

Practical Applications

The practical applications of aluminum die cast motor housings are vast and varied. In the automotive sector, they are used to house the motors in electric power steering systems, where their lightweight nature contributes to overall vehicle weight reduction and improved fuel efficiency. Similarly, in robotics, aluminum motor housings are integral to the structure of robots, providing a stable and sturdy frame that supports complex movements and operations.

Custom Solutions and Product Inquiry

At KT Foundry, we specialize in custom solutions for aluminum motor housings. Whether you require a standard housing for a small electric motor or a customized enclosure for a complex servo system, our expert team is equipped to deliver high-quality solutions that meet your specific requirements. We encourage potential clients to reach out through our website to discuss their needs and explore the vast range of options we offer.

In conclusion, the advancements in aluminum motor housing production, particularly through die casting, have paved the way for more efficient, reliable, and cost-effective motor designs. Our commitment at KT Foundry is to continue innovating and providing our customers with the best possible solutions in aluminum motor housings.