Oil well pump houses play a vital role in the extraction and transportation of crude oil. Within these structures, various components work together to ensure the smooth operation of pumps and motors, ultimately maximizing efficiency and productivity in oil extraction processes. Understanding the significance of key components like pump casings, housings, and bearings is crucial for maintaining optimal performance in oil well operations.

The Importance of Pump Casings in Oil Well Pump Houses

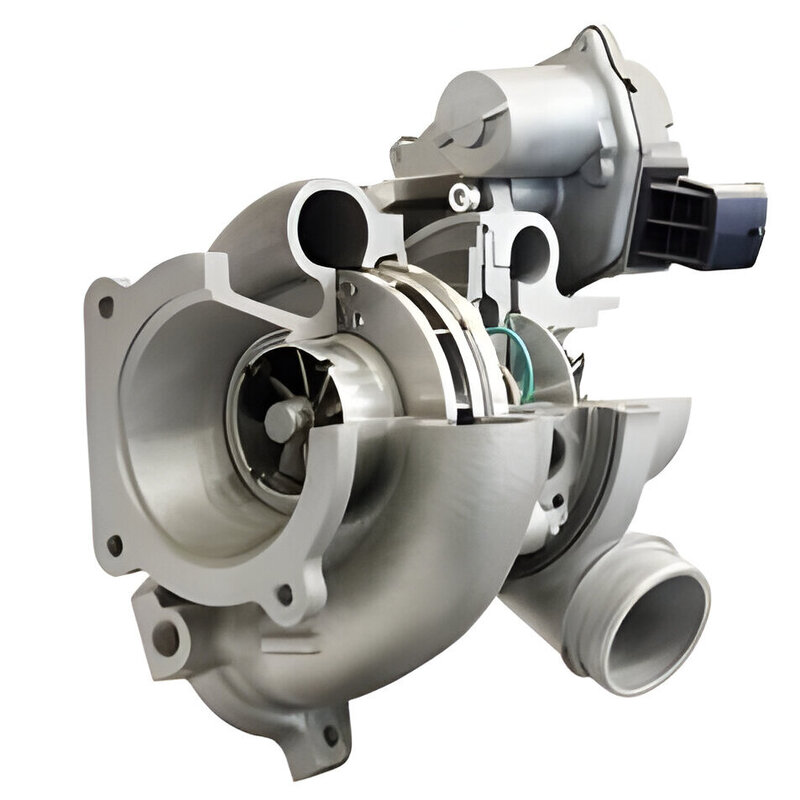

Pump casings serve as the primary enclosure for centrifugal pumps, providing structural support and protection to internal components. The selection of pump casing material is critical to withstand the harsh conditions prevalent in oil well environments. Common materials include cast iron, stainless steel, and aluminum, each offering unique advantages in terms of durability and corrosion resistance.

Centrifugal pump casings, including volute casings and diffuser casings, are designed to optimize fluid flow and pressure within the pump. Volute casings, characterized by their spiral-shaped design, efficiently convert kinetic energy into pressure, essential for pumping crude oil from deep reservoirs. On the other hand, diffuser casings utilize multiple channels to regulate fluid flow, enhancing the pump's efficiency and performance.

Enhancing Durability with Quality Pump Housings and Bearings

Apart from pump casings, pump housings and bearings play crucial roles in supporting the pump's mechanical components. Pump housings, also known as bearing housings, provide a stable platform for mounting bearings and shafts, ensuring proper alignment and reducing vibration during operation. High-quality pump housing materials, such as cast iron or stainless steel, offer superior strength and corrosion resistance, prolonging the lifespan of pump assemblies in oil well environments.

Bearing housing parts, including bearing housings and pump bell housings, are engineered to withstand heavy loads and extreme temperatures commonly encountered in oil extraction processes. Proper maintenance of bearing housing assemblies is essential to prevent premature wear and component failure, ultimately minimizing downtime and operational costs.

Optimizing Performance with Advanced Pump Casing Designs

Innovations in pump casing design have led to the development of specialized components tailored to the unique requirements of oil well applications. Electric motor bell housings and hydraulic pump bell housings provide a protective enclosure for motors and pumps, safeguarding critical components from external contaminants and environmental factors. Additionally, advancements in pump casing materials and manufacturing processes have resulted in lighter, more durable solutions capable of withstanding the rigors of continuous operation in oil field settings.

Water pump casings and fuel pump housings are essential components in oil well pump houses, facilitating the efficient transfer of fluids throughout the extraction process. Whether it's circulating cooling water to maintain optimal operating temperatures or delivering fuel to power machinery and equipment, reliable pump casings and housings are indispensable for uninterrupted oil production operations.

Invest in Quality Components for Superior Performance

In conclusion, oil well pump houses rely on a diverse range of components to ensure uninterrupted operation and maximum productivity. From centrifugal pump casings to bearing housing assemblies, every component plays a crucial role in maintaining efficiency and performance in oil extraction processes. By investing in high-quality pump housings, casings, and bearings, oil companies can minimize downtime, reduce maintenance costs, and optimize overall operational efficiency.