In the world of metal fabrication, precision and safety are paramount. This is where magnetic welding table clamps come into play, offering both seasoned and novice welders enhanced control and reliability. These innovative clamps have transformed workstations into more efficient and secure environments. This article will delve into the functionalities, benefits, and varieties of magnetic welding table clamps, and explore how they integrate into various welding setups.

Understanding Magnetic Welding Table Clamps

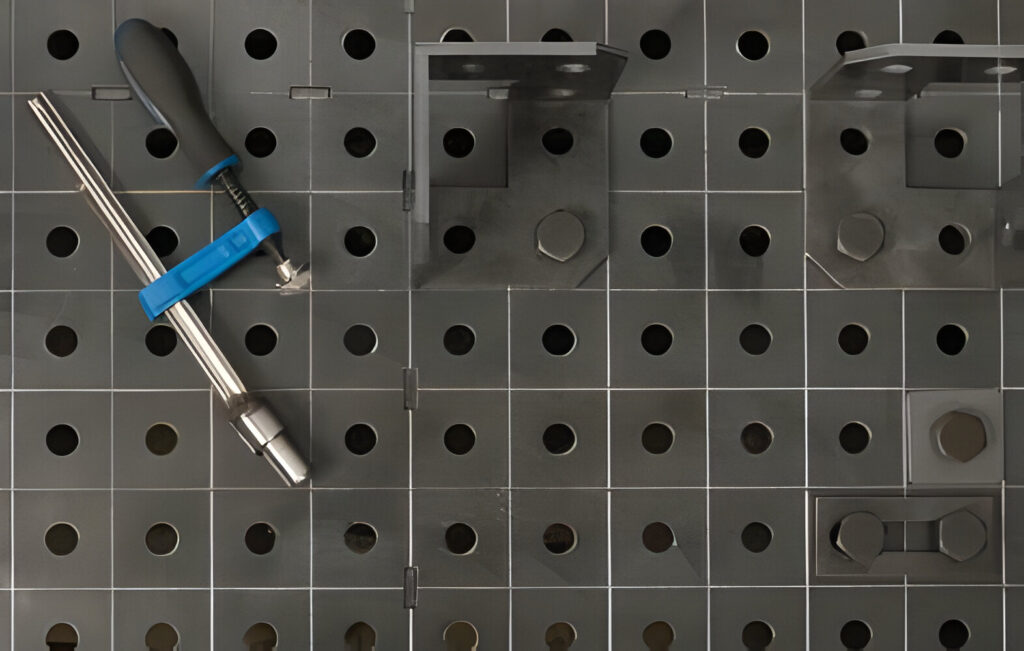

Magnetic welding table clamps are designed to hold metal pieces securely in place on the welding table. Unlike traditional clamps, these magnetic versions leverage powerful magnets to affix themselves and the workpiece to the table. This allows for quick setups and adjustments, which is crucial in high-paced production environments.

One of the key benefits of using magnetic clamps is the reduction of setup time. With these clamps, welders can reposition workpieces quickly without the need to release and re-tighten traditional clamps. Moreover, the strong magnetic hold prevents the metal from shifting during the welding process, thus enhancing the quality and precision of the welds.

Exploring Varieties and Specifications

There are several types of magnetic welding table clamps available, each suited for different tasks and table setups:

- 16mm and 5/8-inch Welding Table Clamps: These are among the most common sizes used in the industry. The 16mm clamps and the 5/8-inch (equivalent to about 16mm) clamps are ideal for handling medium to heavy-duty tasks. They fit perfectly into standard holes in the welding tables, providing a firm grip and ensuring the workpiece remains stable.

- Welding Table Clamping Systems: For more complex projects, a full clamping system might be necessary. These systems often include a variety of clamp sizes and types, such as toggle clamps, slide clamps, and block clamps. Each component works together to provide a comprehensive holding solution that can be customized based on the project requirements.

Practical Applications

Magnetic welding table clamps are versatile and can be used in a variety of welding projects:

- Automotive Assembly: In automotive repair or assembly, magnetic clamps can be used to hold parts such as brackets, panels, and frames. The ability to quickly reposition these parts without compromising the hold is particularly useful in prototype development.

- Fabrication of Metal Furniture: When constructing metal furniture, precision is crucial. Magnetic clamps facilitate precise alignments and adjustments, which are essential for achieving the desired aesthetics and structural integrity.

- General Metal Fabrication: From crafting artistic metal sculptures to constructing industrial machinery, magnetic clamps reduce the physical strain on welders by simplifying the process of setting up and adjusting heavy metal pieces.

Why Choose Our Magnetic Clamps?

At KT-Foundry, we provide a wide array of magnetic welding table clamps that cater to various specifications, including the popular 16mm and 5/8-inch sizes. Our products are crafted using the highest quality materials and technology to ensure durability and efficiency. Whether you're involved in light fabrication tasks or heavy industrial projects, our clamps are designed to meet your needs.

Encouraging Customer Interaction

For more detailed information on our magnetic welding table clamps, including pricing and availability, visit our website at kt-foundry. We encourage potential customers to contact us through our website to discuss how our products can meet your specific welding needs. Our team is dedicated to providing expert advice and support to ensure you select the right tools for your projects.