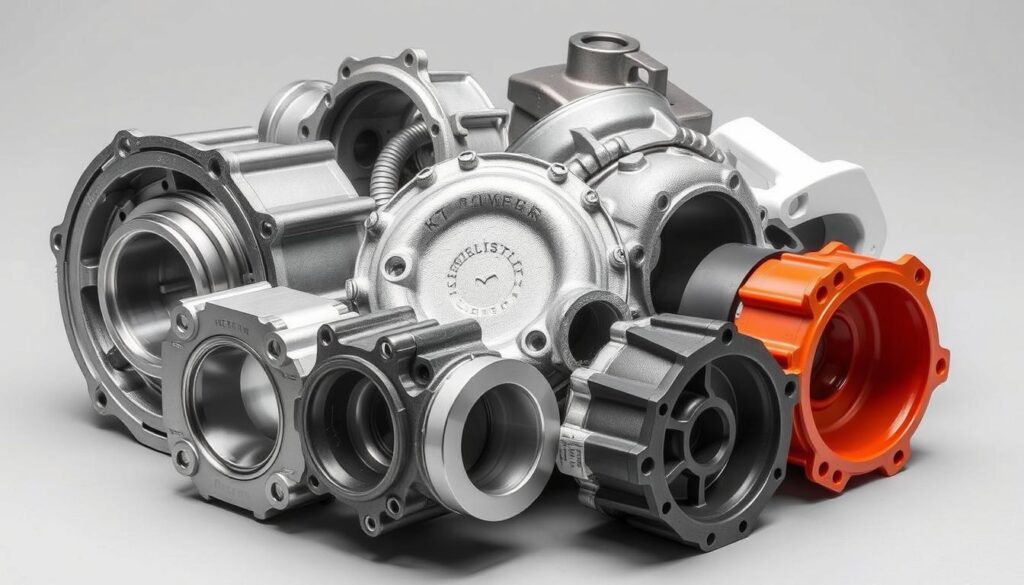

At KT-FOUNDRY, we focus on motor housing, a key part of electric motors. This guide covers the types, materials, and designs of motor housing. It aims to help you improve your projects. We'll look at why motor housing matters, the codes and standards, and the materials used. We'll also discuss how it's made and where it's used.

Key Takeaways

- Comprehensive overview of motor housing types, materials, and designs

- Understanding the importance of motor housing in electric motor performance

- Exploration of common motor housing codes and standards

- Insights into the properties of various motor housing materials

- Examination of the casting processes for motor housing manufacturing

- Diverse applications where motor housing is a critical component

- Valuable resource for optimizing motor-driven equipment and systems

Introduction to Motor Housing

Definition and Importance

Motor housing is the outer casing of an electric motor. It holds the stator, rotor, and bearings inside. This casing is key to the motor's work, reliability, and life span.

It protects the motor's parts. This is crucial for the motor's performance and how well it works.

Types of Motor Housing Codes

Standards like NEMA and IEC set rules for motor housings. These rules cover design, build, and how well they work. They make sure motors are safe and work well everywhere.

| Motor Housing Codes | Key Specifications |

|---|---|

| NEMA |

|

| IEC |

|

Following these codes helps motors work well in different machines and systems. It keeps performance and efficiency steady across the industry.

Motor Housing Materials and Properties

The performance and life of electric motors depend a lot on their housing materials. Motor housings are made from various materials, each with its own benefits. Aluminum and its alloys are popular because they are light, strong, conduct heat well, and resist corrosion.

Manufacturers use die-casting and aluminum extrusion to make motor housings. These methods allow for detailed designs and customization. Other materials like cast iron and plastics are used too, depending on the application's needs.

New advancements in materials and manufacturing are changing motor housing design. Smart materials are being developed to improve comfort, sound, and heat management. The focus is on using eco-friendly materials and new production methods.

| Material | Key Properties | Advantages | Disadvantages |

|---|---|---|---|

| Steel | High strength and rigidity | Robust performance | Heavy, impacting lightweight design |

| Aluminum Alloy | Lightweight, corrosion-resistant | Favorable strength-to-weight ratio | Higher costs, complex processing |

| Carbon Fiber | Extremely lightweight, high strength | Significant weight reduction | Expensive, complex manufacturing |

Choosing materials for motor housing design is a big decision. It involves thinking about performance, cost, and how they are made. Working together, scientists, engineers, and manufacturers can create better, greener, and more efficient motor housing solutions.

"The future of motor housing design is expected to emphasize the use of green, bio-based materials and innovative production methods."

Motor Housing: A Comprehensive Guide to Types, Materials, and Designs

Casting Processes for Motor Housing

The motor housing is key in protecting electric motors and giving them support. Different casting methods are used to make these housings. Each method has its own benefits and challenges.

Sand casting is good for complex shapes and is affordable. But, it might have a rougher finish. Die-casting offers high precision and quality, perfect for detailed work. Gravity casting is simpler and cheaper, great for smaller batches.

Design Considerations and Specifications

Engineers must think about many things when designing motor housings. They need to focus on precision and how well the housing handles heat. This ensures the motor works well and efficiently.

It's also important to follow safety standards and industry rules. Motor housings must be safe and meet certain quality levels. Being able to customize the housing is also key. This lets manufacturers fit the housing to specific needs, whether for big machines or everyday items.

| Casting Process | Advantages | Limitations |

|---|---|---|

| Sand Casting |

|

|

| Die-Casting |

|

|

| Gravity Casting |

|

|

Choosing the right casting method and design is crucial. This way, manufacturers can make motor housings that are top-notch. They meet the needs of many different uses in industry and everyday life.

Applications of Motor Housing

Motor housing is used in many industries. It's found in industrial equipment, cars, and even in new energy tech. In factories, it protects and cools the motors of machines like pumps and compressors.

In cars, it's key for electric and hybrid vehicles. It helps power the car and its systems. The right design and materials are important for better performance and energy use.

It's also used in gadgets, tools, and medical gear. Here, it's all about being tough, managing heat, and being customizable. Making these housings involves choosing the right materials and design. It's all about keeping things running smoothly and safely.

| Industry | Application | Material | Weight | Tolerance |

|---|---|---|---|---|

| Industrial Equipment | Pumps, Compressors, Conveyors, Machine Tools | EN-GJS-400-15 | 82 kg | +/- 0.05 mm |

| Automotive | Electric/Hybrid Vehicles, HVAC Systems | EN-GJS-400-15 | 82 kg | +/- 0.05 mm |

| Consumer Electronics | Power Tools, Robotics, Medical Equipment | EN-GJS-400-15 | 82 kg | +/- 0.05 mm |

Motor housing is crucial for many devices. It boosts performance, reliability, and lifespan. This is true for everything from big machines to small gadgets and new energy solutions.

"The design of motor housing packaging requires consideration of mechanical structure rationality, reliability of packaging material, sealing requirements, and electromagnetic compatibility, emphasizing the use of CAD, CAM, and simulation for verification and optimization."

Conclusion

Motor housing plays a key role in how well electric motors work. It affects their performance, efficiency, and reliability. KT-FOUNDRY offers solutions that fit the needs of many industries.

Need a custom motor housing or want to improve your current equipment? Our experts are ready to help. We use the latest tech and methods to make sure your motor housing works great.

Our solutions, like Aluminum Motor Housing Extrusion, are designed for various industries. They offer benefits like being lightweight and resistant to corrosion. Reach out to us to see how we can enhance your motor systems and help your business grow.

Our company has an advantage in making pump shells

In the competitive manufacturing industry, we’ve gained a strong edge in producing high-quality pump shells. Using advanced technology and precise methods, we ensure our products exceed industry standards for durability and performance. Our stable production process allows us to consistently meet client demands, reducing lead times and ensuring smooth supply chains.

By working closely with our clients, we tailor solutions that meet their specific needs, strengthening relationships and fostering long-term partnerships. If you’re looking for reliable, high-performing pump shells, we’d be happy to provide a quote and discuss your requirements. Feel free to send us an inquiry!