The housing of an electric motor may seem like a simple component, but its impact on motor performance is profound. As the protective enclosure that houses critical internal components, the housing plays a crucial role in safeguarding the motor from environmental factors, supporting structural integrity, and facilitating efficient operation. Understanding the effects of housing on electric motor performance is essential for optimizing efficiency, reliability, and longevity in various applications.

1. Protection from Environmental Factors

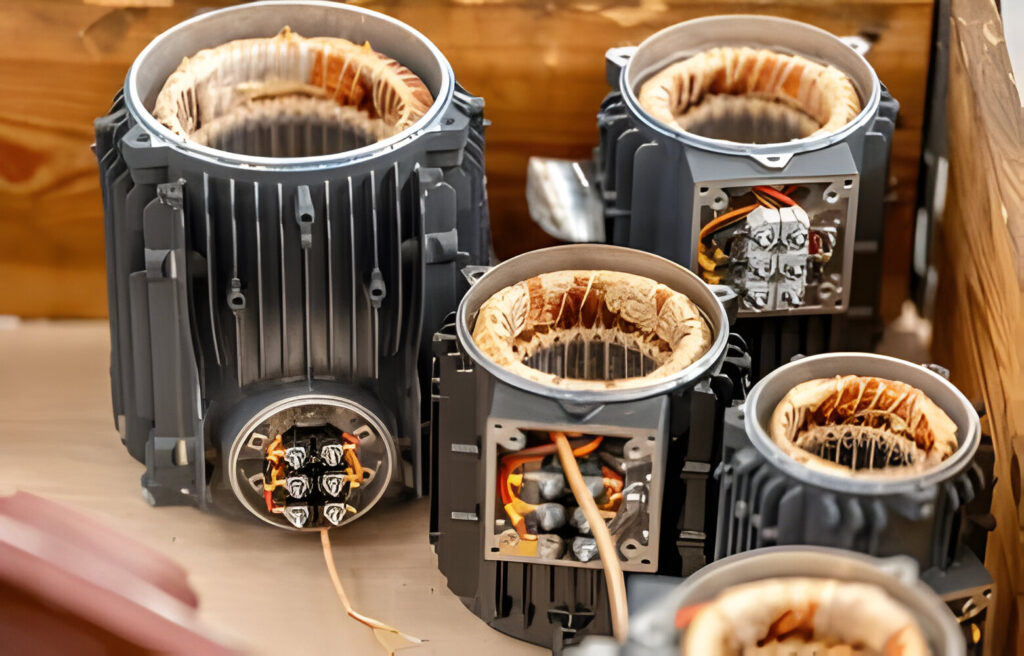

Motor housings, also known as motor casings or housing covers, serve as a barrier between the internal components of the electric motor and external elements such as dust, moisture, chemicals, and debris. By creating a sealed enclosure, the housing prevents contaminants from entering the motor assembly, reducing the risk of premature wear, corrosion, and damage to sensitive components.

2. Thermal Management

Efficient heat dissipation is critical for maintaining optimal operating temperatures in electric motors. The housing plays a vital role in facilitating heat transfer away from the motor components, preventing overheating and ensuring efficient operation. Proper ventilation and thermal insulation within the housing help dissipate heat generated during motor operation, prolonging the lifespan of the motor and improving overall performance.

3. Vibration Dampening

Electric motors generate vibrations during operation, which can affect performance, reliability, and comfort. The housing helps dampen vibrations by providing a stable and secure enclosure for the motor components, reducing noise and minimizing wear on mechanical parts. By absorbing and dispersing vibrations, the housing contributes to smoother and quieter motor operation, enhancing user experience and reducing maintenance requirements.

4. Structural Support

In addition to protection and thermal management, the housing provides structural support for the electric motor assembly. It helps maintain alignment and stability of internal components, reducing the risk of misalignment, friction, and mechanical stress. A sturdy and well-designed housing ensures that the motor operates smoothly and reliably under various operating conditions, enhancing overall performance and durability.

5. Customization for Specific Applications

Different applications require specific housing designs and materials to meet unique requirements and operating environments. Whether it's automotive, industrial, or residential applications, the housing can be customized to accommodate size constraints, mounting configurations, and environmental conditions. Customization options such as material selection, surface finishes, and sealing mechanisms allow for tailored solutions that optimize performance and reliability for specific applications.

Partner with KT Foundry for Premium Motor Housings

At KT Foundry, we specialize in manufacturing high-quality motor housings and components that meet the diverse needs of our clients. From standard motor casings to custom-designed solutions, we offer a comprehensive range of products crafted with precision and expertise.

Contact us today to learn more about our motor housing offerings and how we can support your manufacturing needs. Experience the difference with KT Foundry as your trusted partner in motor housing solutions.