In the realm of electric motors, the significance of motor housing casting cannot be overstated. This intricate process lies at the heart of manufacturing robust motor casings, ensuring optimal performance and longevity. At KT Foundry, we take pride in our expertise in motor housing casting, delivering top-notch solutions that meet the stringent demands of various industries.

Motor housing, also known as motor casing or motor housing cover, serves as the protective enclosure for the intricate components of an electric motor. It shields the internal mechanisms from external elements, mechanical stresses, and temperature variations, thereby safeguarding the motor's functionality. The quality of the motor housing directly impacts the reliability and efficiency of the motor itself.

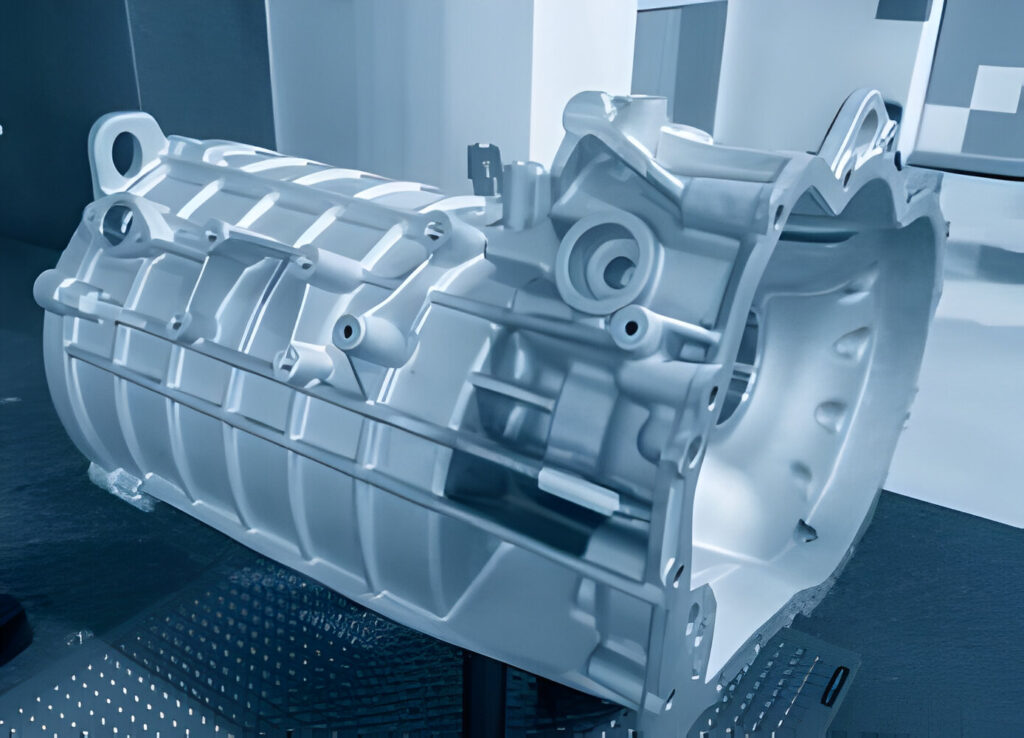

At KT Foundry, we specialize in producing premium motor housing parts through precision casting techniques. Our process involves the meticulous pouring of molten metal, typically aluminum or cast iron, into molds to create the desired shape of the motor housing. This method ensures uniformity, strength, and dimensional accuracy, crucial for seamless integration with electric motors.

The electric motor casing plays a pivotal role in dissipating heat generated during operation, preventing overheating and subsequent damage to internal components. Our motor housing casting techniques prioritize thermal conductivity, allowing efficient heat transfer away from critical areas. This optimization enhances the motor's performance and extends its service life, contributing to cost savings and operational reliability.

Our electric motor housing solutions cater to diverse applications across industries, ranging from automotive and aerospace to industrial machinery and renewable energy. Whether it's a compact motor housing for electric vehicles or a robust enclosure for heavy-duty industrial motors, we tailor our casting processes to meet specific requirements and performance standards.

The expertise of our engineers and technicians ensures that each motor housing casting meets the highest quality standards. We employ advanced technologies and rigorous quality control measures throughout the production cycle, from material selection to final inspection. This commitment to excellence guarantees superior products that surpass customer expectations.

In addition to standard motor housing designs, we offer customization options to accommodate unique specifications and design preferences. Our engineering team collaborates closely with clients to understand their specific requirements and develop tailored solutions that optimize performance, durability, and cost-efficiency.

Whether you require a single prototype or mass production of motor housing components, KT Foundry has the capabilities and expertise to fulfill your needs. Our streamlined production processes and flexible manufacturing capabilities enable us to deliver cost-effective solutions without compromising quality or lead times.

Experience the difference that precision motor housing casting can make in your electric motor applications. Contact us today through our website (kt-foundry) to discuss your project requirements with our team of experts. Let us partner with you to unlock the full potential of your electric motor systems.