In the world of cars, what engine block you choose matters a lot. It affects how well your car runs, how much fuel it uses, and what it can do. Aluminum blocks are becoming more popular because they offer big advantages over old cast iron blocks. We'll look at why aluminum blocks are good, how they perform, and where they're used.

Key Takeaways

- Aluminum engine blocks are much lighter than cast iron, making cars run better and use less fuel.

- Aluminum can be shaped in many ways, leading to new engine designs and better parts fit.

- Aluminum blocks are great at cooling down, keeping engines from getting too hot.

- Aluminum alloys are strong and last long, perfect for fast cars and heavy-duty use.

- Aluminum engine blocks work with many modern engines, making them a good choice for many cars.

Unveiling the Advantages of Aluminum Engine Blocks

In the world of engine design and making, what materials you use is key. Aluminum has changed the game. It brings many benefits to engine design and building.

Weight Reduction: A Game-Changer for Performance

Aluminum engine blocks are much lighter than old cast iron ones. This lightness boosts a car's acceleration, handling, and fuel efficiency. It makes the car quicker and more fun to drive.

Casting Flexibility: Shaping the Future of Engine Design

Aluminum's casting flexibility is amazing. It lets designers make engines in new ways. They can add cool features like intricate coolant passages and optimized cylinder head placement.

This makes engines better and more efficient. Aluminum is key in making engines better for the future.

The Evolution of Aluminum Engine Block Technology

Aluminum engine blocks have been around for decades. The technology behind them has evolved over time. More engine manufacturers now use aluminum engine blocks, showing their many advantages.

In the early days, making complex aluminum engine blocks was hard. But, new manufacturing processes have made it easier. Today, new aluminum alloys have improved these blocks' performance and durability. This makes them a favorite among engine builders and manufacturers.

One big plus of aluminum engine blocks is how much lighter they are. This can make a car run better and use less fuel. Also, aluminum's flexibility lets engine designers try new and exciting designs. This pushes the limits of what's possible in engine design.

| Advantage | Description |

|---|---|

| Weight Reduction | Aluminum engine blocks are 30-50% lighter than cast iron ones. This leads to better fuel efficiency and performance. |

| Casting Flexibility | Aluminum can be molded into complex shapes. This lets engine builders design for more power, efficiency, and better packaging. |

| Corrosion Resistance | Aluminum alloys resist corrosion well. This means engine blocks last longer and work reliably in different conditions. |

As aluminum engine block technology has grown, they've become more appealing to engine makers. They offer benefits like being lighter, more flexible in design, and more durable. With these advancements, we can look forward to seeing aluminum engine blocks play a key role in future engine designs and performance.

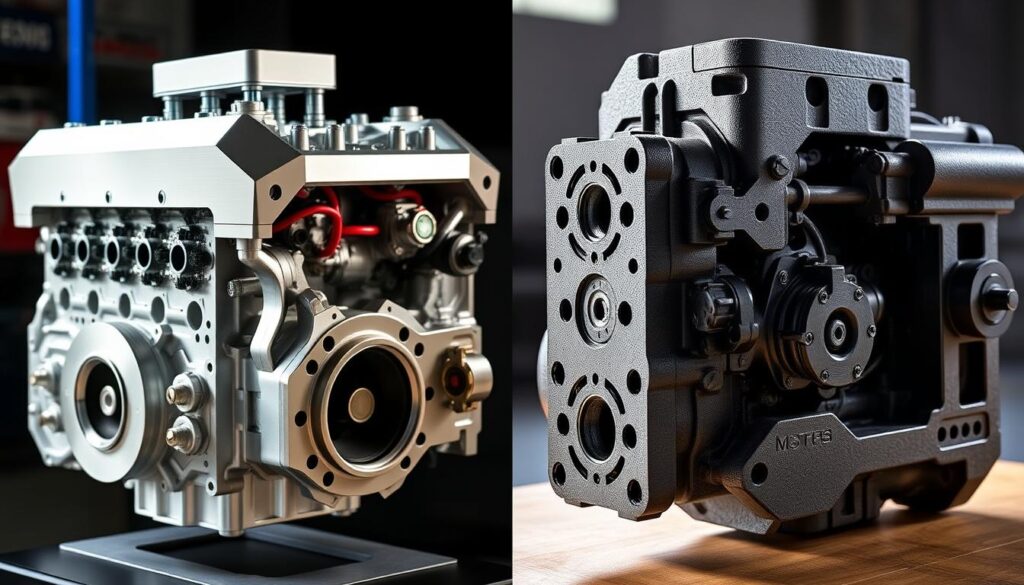

Comparing Aluminum vs. Cast Iron Engine Blocks

The debate between aluminum and cast iron engine blocks is ongoing. Cast iron has been favored for its strength and durability. Yet, aluminum engine blocks are gaining attention for their heat dissipation abilities.

Heat Dissipation: Keeping Cool Under Pressure

Aluminum engine blocks excel at cooling down. They are very good at moving heat away from important areas. This is crucial when the engine is working hard, like during fast starts or long drives.

Cast iron blocks, though strong, don't cool as well. They can get too hot, especially when the engine is under stress. This can hurt performance, reduce fuel efficiency, and even damage the engine over time.

| Characteristic | Aluminum Engine Blocks | Cast Iron Engine Blocks |

|---|---|---|

| Heat Dissipation | Excellent | Moderate |

| Thermal Conductivity | High | Low |

| Durability | Good | Excellent |

| Weight | Lighter | Heavier |

Aluminum engine blocks keep the engine cool, even when it's working hard. This leads to better performance, more fuel efficiency, and reliability. These are key for today's fast cars.

Exploring the Strength and Durability of Aluminum Alloys

Aluminum engine blocks are made with special aluminum alloys. These alloys are designed to be strong, durable, and resistant. They can handle the tough conditions inside engines, like the force from pistons and high temperatures.

Aluminum alloys have a high tensile strength. This means they can keep the engine's structure strong. Unlike cast iron, which can break easily, aluminum alloys are less likely to crack or bend. This makes them great for engines, including diesel and internal combustion engines.

| Property | Aluminum Alloy | Cast Iron |

|---|---|---|

| Tensile Strength | High | Moderate |

| Porosity Resistance | Excellent | Average |

| Thermal Conductivity | Good | Poor |

| Machinability | Much Harder | Easier |

Also, the way these aluminum alloy engine blocks are made helps them resist porosity. This means they can keep out dirt and stay strong over time. This is key for keeping the engine running well, even when it's pushed hard.

"The strength and durability of our aluminum alloy engine blocks are unparalleled, ensuring optimal performance and reliability for our customers."

Aluminum Engine Blocks in High-Performance Applications

Aluminum engine blocks are changing the game in high-performance and racing. They are light and can handle more power and torque. This makes them great for both enthusiasts and professional racers.

Thanks to new alloys like A356, engine builders can make aftermarket aluminum blocks. These blocks can take on high-horsepower and high-torque engines. This has made aluminum blocks even more popular.

Boosting Horsepower and Torque Capabilities

Aluminum engine blocks are a big win for high-performance applications. They let you boost horsepower and torque a lot. Aluminum is lighter than cast iron, so it makes engines more powerful for their size.

This means racers can go faster and get better acceleration. It's why aluminum blocks are a top pick for enthusiasts and engine builders who want the best performance.

- Lightweight construction for enhanced power-to-weight ratio

- Ability to withstand high levels of horsepower and torque

- Increased responsiveness and acceleration for high-performance applications

- Favored by enthusiasts and race teams for their industry-leading capabilities

"Aluminum engine blocks have revolutionized the way we approach high-performance engine design. Their combination of lightweight construction and exceptional strength allows us to push the boundaries of what's possible in terms of horsepower and torque capabilities."

The demand for high-performance applications keeps growing. This means the market for aluminum engine blocks will keep growing too. 319 aluminum and other advanced alloys are key to meeting the automotive industry and aftermarket blocks needs.

Aluminum Engine Block Compatibility with Modern Engines

The car world keeps changing, and aluminum engine blocks fit right in. They work well with new and old cars alike. These blocks are light and flexible, fitting with many engine parts, even those made of cast iron.

Thanks to better aluminum casting and machining, these blocks are a hit. They mix performance, efficiency, and easy fitting with today's engines perfectly.

Adaptability to Engine Upgrades

Aluminum engine blocks are great for engine tweaks. They support power boosts and performance upgrades. This makes them a top pick for both new and classic car fans.

| Metric | Aluminum Engine Block | Cast Iron Engine Block |

|---|---|---|

| Weight | Lighter | Heavier |

| Thermal Conductivity | Higher | Lower |

| Corrosion Resistance | Better | Adequate |

| Machining Flexibility | Greater | Limited |

The table shows how aluminum blocks beat cast iron ones. They're lighter, better at cooling, more resistant to rust, and easier to make. These traits help them fit well with modern engines.

As car tech advances, aluminum engine blocks will keep being a key part. They're essential for better engine performance and efficiency.

Thermal Management Strategies for Aluminum Engine Blocks

Keeping aluminum engine blocks at the right temperature is key for their performance and life. New coolant systems and heat dissipation methods are used. They help keep the engine block cool, even when it's working hard.

Coolant Systems and Heat Dissipation Techniques

Heavy-duty water jackets are a main strategy for managing heat in aluminum engine blocks. They are designed to pull heat away from important parts of the block. This prevents overheating and ensures the coolant flows well.

Also, special coolants are used to handle high temperatures. These coolants keep working well, even when the engine is under a lot of stress. They help keep the engine block at the right temperature.

- Heavy-duty water jackets for efficient heat transfer

- Carefully engineered coolant flow paths to maximize heat dissipation

- Advanced coolant formulations designed to withstand high temperatures

By using these strategies together, aluminum engine blocks can handle heat well. This means they perform consistently and last longer, even in tough conditions.

"Effective thermal management is the key to unlocking the full potential of aluminum engine blocks."

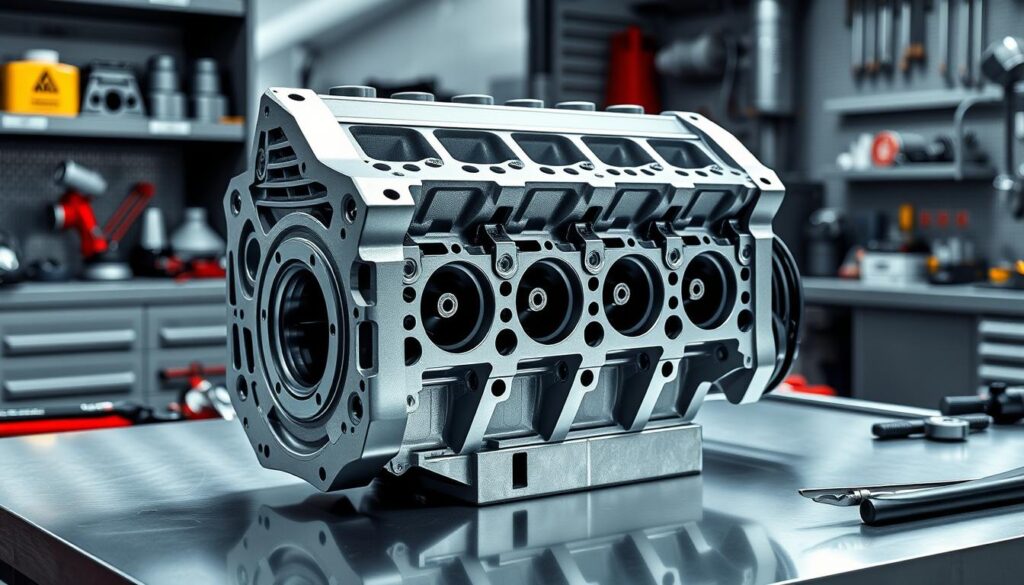

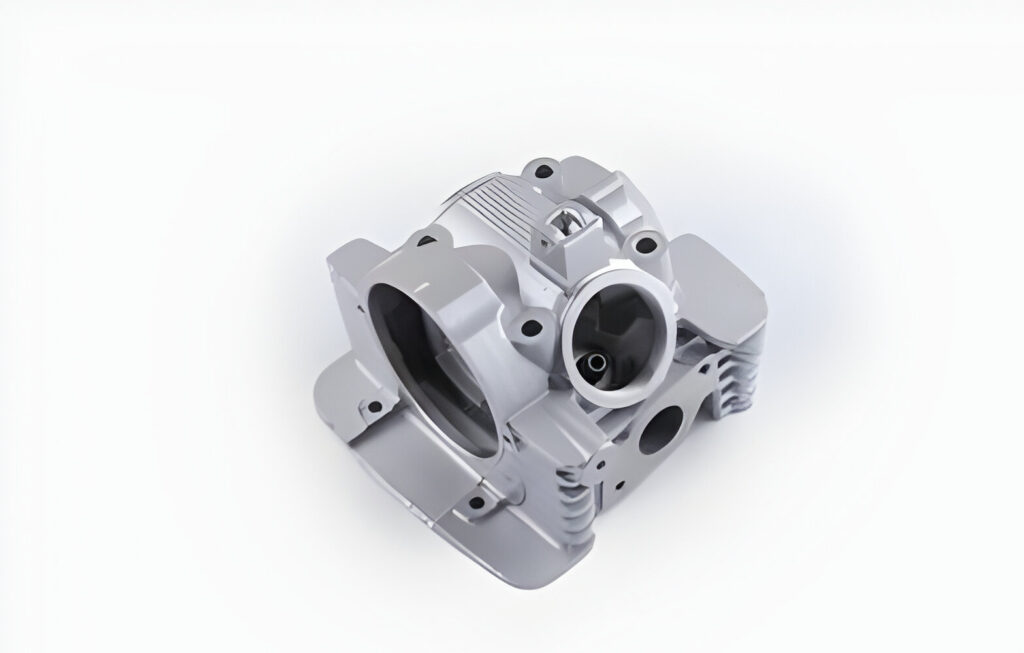

Manufacturing Processes for Aluminum Engine Blocks

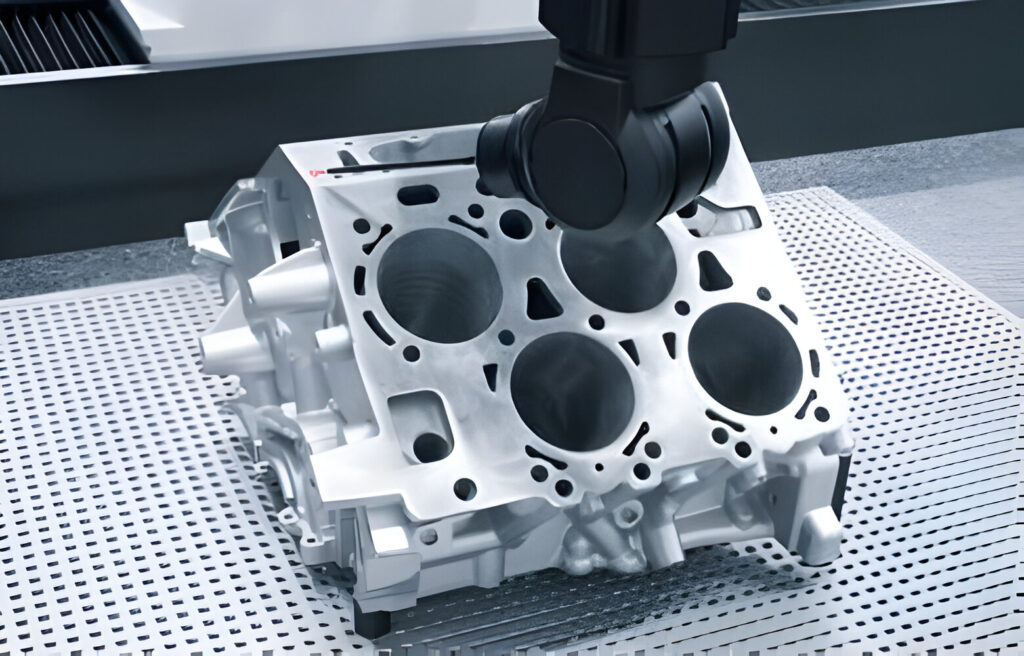

Making aluminum engine blocks is a detailed process. First, a mold is made to match the engine block's design. Then, molten aluminum is poured into the mold, filling every part of the block.

After the aluminum solidifies, the block is taken out of the mold. This step, called casting, makes a single, detailed engine block.

Welding and foundry skills are key for the block's strength and quality. Experts check the block, making any needed fixes or welds to ensure it's durable and performs well.

Importance of the Casting Process

The casting process is vital for making aluminum engine blocks. It allows for precise shaping, ensuring the block's design is perfect for performance and efficiency.

| Manufacturing Step | Description |

|---|---|

| Mold Creation | A specialized mold is designed and fabricated to replicate the desired engine block shape and features. |

| Aluminum Pouring | Molten aluminum is carefully poured into the mold, filling every contour and area of the block. |

| Solidification | The aluminum within the mold is allowed to cool and solidify, forming the engine block structure. |

| Mold Removal | The solidified engine block is carefully extracted from the mold, ready for further processing. |

These steps, along with aluminum's benefits, make these engine blocks popular for high-performance engines.

Quality and detail are crucial in making these engine blocks. By following strict standards and using new technologies, manufacturers create blocks that are strong, durable, and manage heat well.

Cost-Effectiveness and Sustainability of Aluminum Engine Blocks

Aluminum engine blocks are a smart choice for the car industry, especially for passenger cars. They cost less to make and need less upkeep than cast iron blocks. This makes car making more efficient and kinder to the planet.

Lifecycle Analysis and Environmental Impact

Aluminum engine blocks are great because they can be recycled easily. They can be melted down and used again, cutting down on waste. This helps the environment and fits with the idea of a circular economy.

Also, aluminum blocks are lighter, which means cars use less fuel. This is good for the planet because it means less pollution. It's a big win for those who care about the environment.

| Metric | Aluminum Engine Blocks | Cast Iron Engine Blocks |

|---|---|---|

| Cost-Effectiveness | Higher | Lower |

| Recyclability | Excellent | Good |

| Fuel Efficiency | Improved | Standard |

| Environmental Impact | Lower | Higher |

Using aluminum engine blocks helps make cars better for the planet. It meets the needs of people who want to help the environment and follow the law.

Industry Trends and Future Developments

The industry is pushing the limits of aluminum engine blocks. We're seeing big improvements in performance and reliability. Aluminum blocks are now common in engines like the LS and Chevy V8.

New techniques in sleeving and advanced welding, like TIG welding, are making aluminum blocks better. These blocks are lighter and help keep the engine cool. This is key for top performance.

Car makers are focusing on making cars lighter and more efficient. Aluminum engine blocks play a big role in this. The future looks bright for these blocks, with even more benefits for car lovers and engineers.

| Key Trends | Future Developments |

|---|---|

| Widespread adoption of aluminum blocks in LS and Chevy V8 engines | Continued refinement of sleeving techniques |

| Advancements in TIG welding for aluminum engine blocks | Increased focus on heat management and cooling strategies |

| Weight reduction and efficiency as key priorities | Exploration of new aluminum alloys and manufacturing processes |

As aluminum engine blocks become more common, we'll see more innovation. The future is exciting for these blocks. They promise better performance and reliability for car fans.

Conclusion

Aluminum engine blocks are a great choice compared to traditional cast iron blocks. They offer many benefits that make them popular for modern engines. These benefits include being lighter, more flexible in casting, and better at cooling.

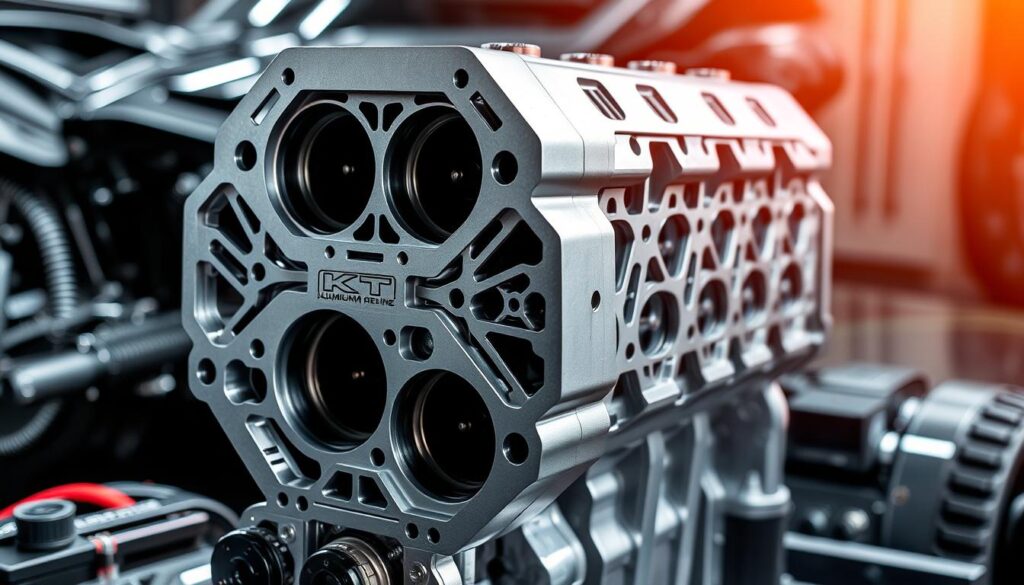

KT-FOUNDRY is a leader in the production of aluminum engine blocks, offering products that combine lightweight construction with exceptional strength and durability. Our advanced manufacturing processes and rigorous quality control ensure that each engine block meets the highest standards of performance and reliability. We utilize state-of-the-art casting techniques and high-grade aluminum alloys to produce engine blocks that excel in thermal efficiency and corrosion resistance. Additionally, we provide customized solutions tailored to specific engine designs and performance requirements.

To help us better address your needs, please fill out the form below, and we will provide a solution tailored to your specifications.

KT-Foundry.

Bring Your Designs to Reality– Experience Custom Perfection with On-Demand CNC Machining!