Motor housings are crucial components in the world of machinery, providing protection and support to electric motors. But have you ever wondered what materials are used to make these essential enclosures? Understanding what motor housings are made of is essential for optimizing performance, durability, and efficiency in various industrial and residential applications. Let's delve into the materials commonly used in motor housing manufacturing and explore their characteristics and benefits.

1. Aluminum: Lightweight and Versatile

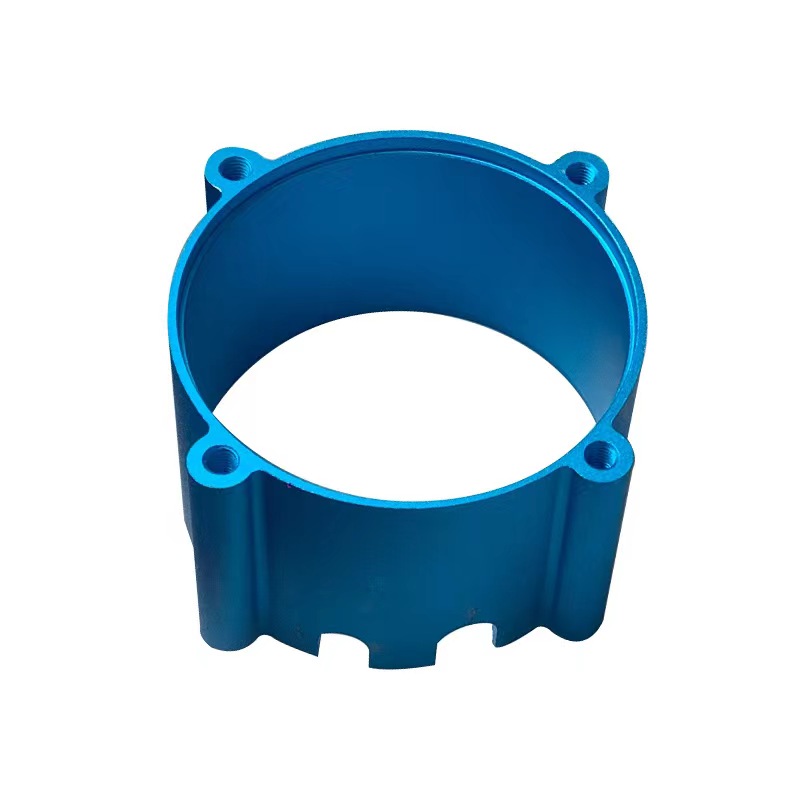

Aluminum is a popular choice for motor housing construction due to its lightweight nature, excellent thermal conductivity, and corrosion resistance. Aluminum motor housings offer a perfect balance of strength and weight, making them ideal for applications where weight reduction is crucial without compromising durability.

Aluminum motor housings are commonly used in automotive, aerospace, and electronics industries, where heat dissipation and performance are critical factors. The versatility of aluminum allows for intricate designs and precise machining, ensuring optimal functionality and performance in electric motors.

2. Cast Iron: Robust and Durable

Cast iron motor housings are renowned for their exceptional strength, durability, and resistance to wear and tear. Cast iron offers superior mechanical properties, making it suitable for applications that require robust and long-lasting motor enclosures.

While cast iron motor housings may be heavier compared to aluminum counterparts, they provide superior protection against mechanical stress, vibration, and impact. These properties make cast iron motor housings ideal for heavy-duty industrial machinery, marine applications, and outdoor equipment where durability and resilience are paramount.

3. Steel: Strength and Reliability

Steel motor housings are prized for their strength, rigidity, and resistance to deformation under heavy loads. Steel offers excellent mechanical properties, including high tensile strength and impact resistance, making it an ideal material for motor housings in demanding applications.

Steel motor housings provide reliable protection for electric motors operating in harsh environments, such as construction equipment, mining machinery, and agricultural vehicles. The corrosion-resistant properties of certain steel alloys further enhance the longevity and performance of motor housings in challenging conditions.

4. Thermoplastics: Lightweight and Cost-Effective

Thermoplastic materials, such as polyethylene, polypropylene, and ABS (acrylonitrile butadiene styrene), are increasingly being used in motor housing manufacturing due to their lightweight nature, ease of processing, and cost-effectiveness.

Thermoplastic motor housings offer advantages such as corrosion resistance, electrical insulation, and design flexibility. These materials are commonly used in consumer electronics, appliances, and small motors where weight reduction, cost efficiency, and aesthetic considerations are essential.

Choosing the Right Material for Your Application

Selecting the appropriate material for motor housing construction depends on various factors, including:

- Application requirements

- Environmental conditions

- Operating temperatures

- Weight considerations

- Cost constraints

At KT Foundry, we specialize in manufacturing motor housings using a variety of materials to meet the diverse needs of our clients. From aluminum and cast iron to steel and thermoplastics, we offer customized solutions tailored to specific applications and specifications.

Contact us today to learn more about our motor housing offerings and how we can support your manufacturing needs. Experience the difference with KT Foundry as your trusted partner in motor housing solutions.